In the ever-evolving world of construction, where budgets are tight and competition is fierce, Value Engineering (VE) has emerged as a powerful tool for optimising project outcomes. It’s a systematic process that goes beyond simply cutting costs; it’s about maximizing value by ensuring every component of a project delivers the most significant benefit at the least expense. This comprehensive guide delves into the world of value engineering in construction, empowering all stakeholders, from architects and engineers to contractors and owners, to leverage its potential for building smarter and achieving project success.

VE is a systematic method of improving the value of a project by optimizing its function and reducing costs without compromising on quality. In the construction industry, value engineering plays a crucial role in enhancing project outcomes by balancing cost, performance, and quality. This approach is particularly valuable in a country like India, where the demand for high-quality infrastructure and buildings is growing, and the need for cost-effective solutions is more critical than ever.

Introduction to Value Engineering in Construction

VE is a practice that originated during World War II when there were shortages of materials and a need to find alternatives without compromising on performance. In the construction industry, value engineering involves a detailed analysis of various project elements, including design, materials, methods, and construction techniques, to identify opportunities for cost savings while maintaining or improving quality and performance.

The primary goal of value engineering is to deliver maximum value to the client by reducing costs and improving efficiency, which ultimately leads to enhanced construction quality. This process is particularly relevant in the Indian construction sector, where developers and contractors are constantly seeking ways to optimize costs due to budget constraints while still delivering high-quality projects.

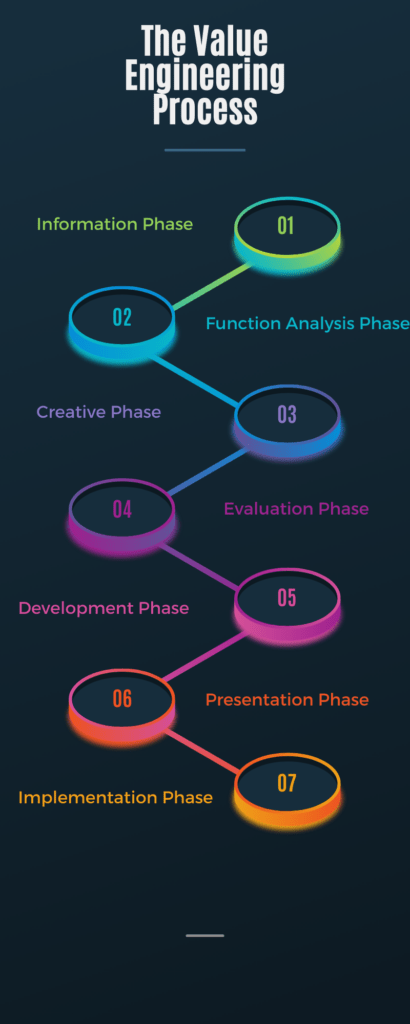

The Value Engineering Process

The value engineering process typically follows a structured methodology known as the Value Methodology (VM), which consists of the following key steps:

- Information Phase: Gather comprehensive data about the project, including its objectives, functions, costs, and performance criteria. This phase involves identifying the client’s requirements and understanding the constraints and opportunities within the project.

- Function Analysis Phase: Break down the project into its essential functions and determine the cost and performance of each function. This phase aims to identify the most critical functions that provide value to the project and those that may require optimization.

- Creative Phase: Generate a wide range of ideas and alternatives for achieving the required functions at a lower cost or with improved performance. This brainstorming phase encourages innovative thinking and creative solutions.

- Evaluation Phase: Assess the feasibility, cost, and performance of the ideas generated during the creative phase. This phase involves selecting the most promising alternatives and evaluating their impact on the project.

- Development Phase: Develop the selected alternatives into practical solutions and prepare detailed proposals, including cost estimates, technical specifications, and implementation plans. This phase requires collaboration between various stakeholders, including designers, engineers, and contractors.

- Presentation Phase: Present the value engineering proposals to the client and project team for approval. This phase involves communicating the benefits of the proposed solutions and addressing any concerns or objections.

- Implementation Phase: Implement the approved value engineering proposals during the construction phase. This phase requires careful coordination and monitoring to ensure that the proposed changes are executed correctly and deliver the desired outcomes.

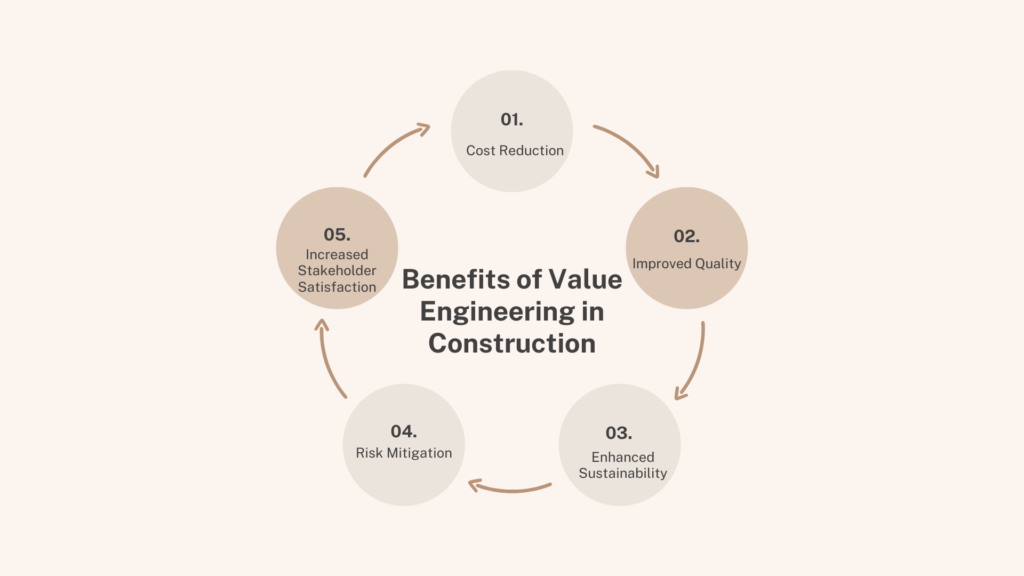

Benefits of Value Engineering in Construction

VE offers several benefits in the construction industry, particularly in the context of the Indian market:

- Cost Reduction: One of the primary benefits of VE is cost reduction. By optimizing design, materials, and construction methods, value engineering can significantly reduce project costs without compromising on quality. For example, in a high-rise residential project in Mumbai, the use of alternative construction materials, such as lightweight concrete and recycled steel, reduced material costs by 15% while maintaining structural integrity.

- Improved Quality: VE focuses on enhancing the value of a project by improving its quality and performance. This approach ensures that the project meets or exceeds the client’s expectations while adhering to industry standards and regulations. For instance, in a commercial office project in Bangalore, value engineering led to the selection of advanced HVAC systems that improved indoor air quality and energy efficiency.

- Enhanced Sustainability: VE promotes the use of sustainable materials and construction practices, which can lead to environmentally friendly and energy-efficient buildings. In the context of India, where sustainability is becoming a key consideration in construction, value engineering can help developers achieve green building certifications and reduce their carbon footprint. An example is the construction of a LEED-certified hospital in Delhi, where value engineering helped optimize energy usage and water conservation measures.

- Risk Mitigation: By analyzing and optimizing various project elements, VE helps identify potential risks and develop strategies to mitigate them. This proactive approach reduces the likelihood of cost overruns, delays, and quality issues. For example, in a large infrastructure project in Chennai, VE identified potential geological risks that could impact foundation stability, leading to the adoption of a more robust foundation design.

- Increased Stakeholder Satisfaction: VE involves collaboration between various stakeholders, including clients, designers, engineers, and contractors, to achieve the best possible outcomes. This collaborative approach fosters transparency, trust, and satisfaction among all parties involved. In a mixed-use development project in Hyderabad, VE workshops with stakeholders helped align project goals and expectations, resulting in a successful project delivery.

Value Engineering Examples in Indian Construction

To illustrate the impact of value engineering in the Indian construction industry, let’s consider a few real-life examples:

- Residential Complex in Pune: A residential complex in Pune faced challenges in meeting the client’s budget constraints while ensuring high-quality construction. The value engineering team conducted a thorough analysis of the project design and identified opportunities for cost savings in the structural and architectural elements. By using post-tensioned slabs instead of conventional reinforced concrete slabs, the team reduced material costs by 12% and shortened the construction timeline by 20%. Additionally, the use of prefabricated components for the facade reduced labor costs and improved construction quality.

- Metro Rail Project in Delhi: The Delhi Metro Rail Corporation (DMRC) implemented value engineering in the construction of Phase III of the Delhi Metro. The value engineering team identified opportunities for cost savings in the design of the stations and viaducts. By optimizing the alignment of the tracks and reducing the number of columns, the team reduced construction costs by 10% and minimized the impact on the surrounding environment. Additionally, the use of energy-efficient lighting and ventilation systems in the stations contributed to significant operational cost savings.

- Green Building in Chennai: A commercial building in Chennai aimed to achieve a Platinum LEED certification for sustainability. The value engineering team analyzed various aspects of the building design, including the HVAC system, building envelope, and water management system. By selecting high-performance glazing and insulation materials, the team reduced energy consumption by 25% and improved indoor comfort. The use of a rainwater harvesting system and low-flow plumbing fixtures reduced water consumption by 30%, contributing to the building’s sustainability goals.

Challenges in Implementing Value Engineering

While value engineering offers numerous benefits, its implementation in the construction industry is not without challenges, particularly in the Indian context:

- Resistance to Change: One of the significant challenges in implementing value engineering is resistance to change from stakeholders who may be hesitant to adopt new methods or materials. Overcoming this resistance requires effective communication and demonstration of the benefits of value engineering.

- Lack of Awareness and Training: In India, there is a lack of awareness and training on value engineering among construction professionals. This gap can be bridged through workshops, seminars, and training programs to educate stakeholders on the principles and benefits of value engineering.

- Coordination Among Stakeholders: Value engineering requires collaboration among various stakeholders, including clients, designers, engineers, and contractors. Ensuring effective coordination and communication among these parties can be challenging, particularly in large and complex projects.

- Time Constraints: Value engineering requires a thorough analysis of the project elements, which can be time-consuming. In projects with tight deadlines, allocating sufficient time for value engineering may be challenging, requiring careful planning and prioritization.

- Balancing Cost and Quality: While the primary goal of value engineering is cost reduction, it is essential to balance cost savings with quality and performance. Achieving this balance requires a comprehensive understanding of the project requirements and careful evaluation of the proposed solutions.

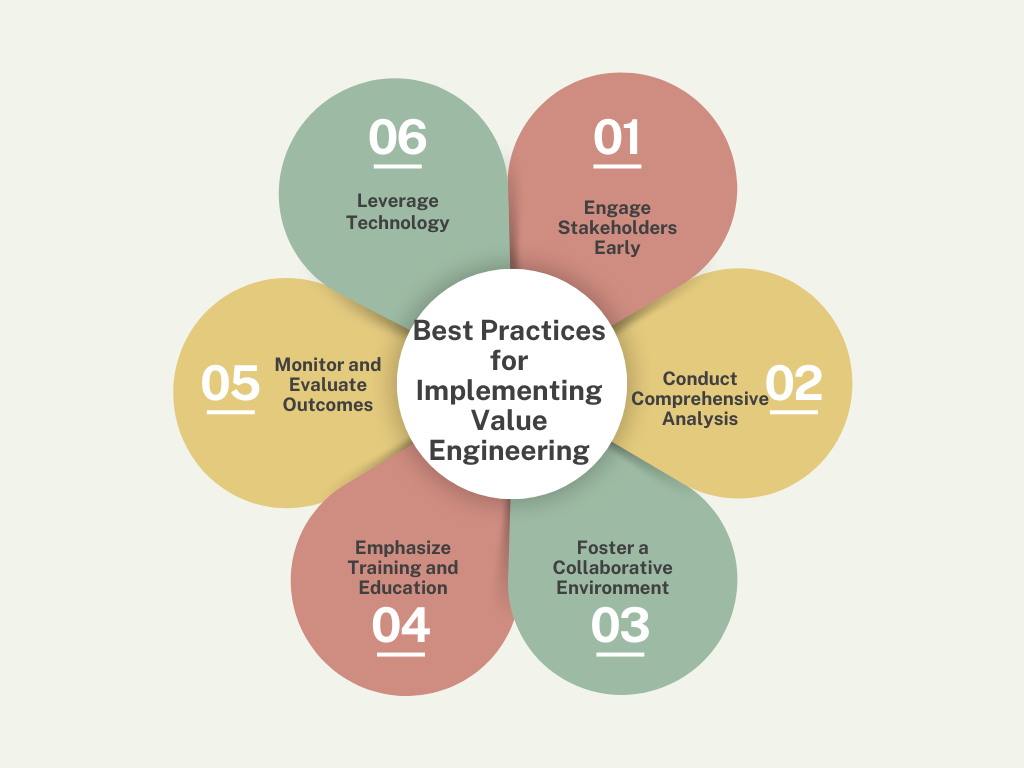

Best Practices for Implementing Value Engineering

To maximize the benefits of value engineering in construction, it is essential to follow best practices that ensure effective implementation:

- Engage Stakeholders Early: Involve all key stakeholders, including clients, designers, engineers, and contractors, early in the value engineering process to ensure alignment of project goals and expectations.

- Conduct Comprehensive Analysis: Perform a thorough analysis of the project elements, including design, materials, methods, and construction techniques, to identify opportunities for cost savings and quality improvement.

- Foster a Collaborative Environment: Encourage open communication and collaboration among stakeholders to facilitate the exchange of ideas and foster innovation.

- Emphasize Training and Education: Provide training and education on value engineering principles and practices to enhance the skills and knowledge of construction professionals.

- Monitor and Evaluate Outcomes: Continuously monitor and evaluate the outcomes of value engineering initiatives to ensure they deliver the desired benefits and make adjustments as needed.

- Leverage Technology: Utilize advanced technologies, such as Building Information Modeling (BIM) and construction management software, to enhance the value engineering process and improve decision-making.

Conclusion

VE is a powerful tool for enhancing construction quality and efficiency in the Indian context. By optimizing project elements and balancing cost, performance, and quality, value engineering can deliver significant benefits to clients, developers, and contractors. Implementing value engineering effectively requires a comprehensive understanding of the project requirements, a collaborative approach, and a commitment to continuous improvement. As the demand for high-quality, cost-effective construction continues to grow in India, value engineering will play an increasingly important role in shaping the future of the construction industry.