Just in Time (JIT) is a strategy in construction that focuses on receiving materials right when they’re needed, rather than stockpiling them in advance. The goal is to align the delivery of materials with the project timeline to avoid unnecessary storage costs, reduce waste, and keep the site organized. This approach helps prevent delays caused by missing materials while also avoiding the clutter and expense of overstocked supplies.

JIT works well in construction because it allows for better use of space and resources. Instead of managing large quantities of materials that may sit unused for days or weeks, everything arrives at the moment it’s needed, streamlining operations and enhancing project flow.

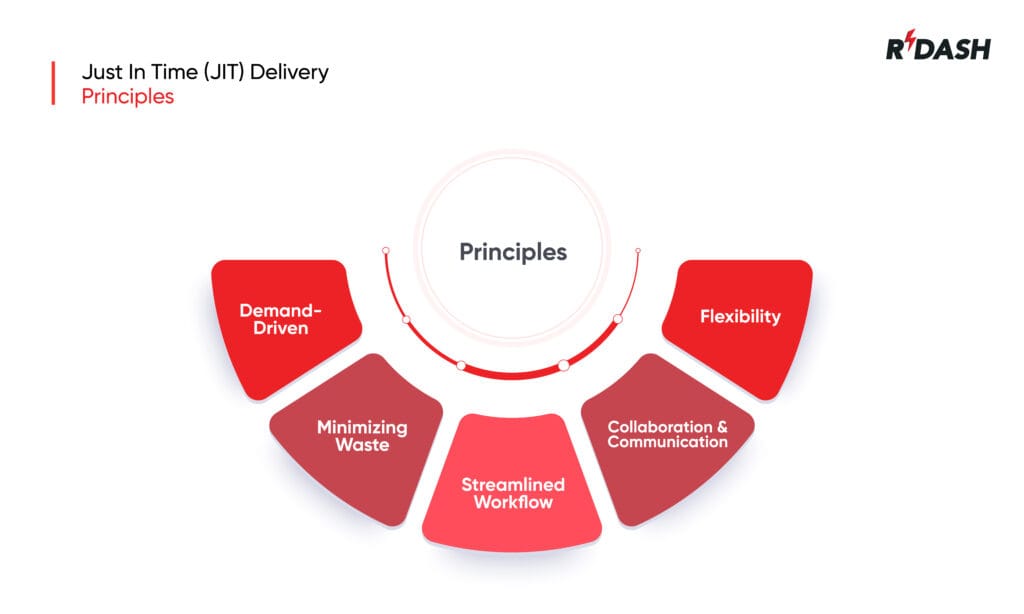

Just-in-Time Principles

At its core, JIT follows a few key principles that make it effective in construction:

Demand-Driven: JIT operates based on actual demand rather than forecasts. In construction, this means ordering materials as they are required for each phase of the project, rather than stockpiling them based on predictions.

Minimizing Waste: One of the biggest advantages of JIT is its focus on reducing waste. By ordering only what’s needed, you avoid over-purchasing materials, which can lead to excess stock, potential damage, and higher costs.

Streamlined Workflow: JIT promotes a smoother and more organized work process. Since materials arrive just in time for use, there’s less need for on-site storage and fewer opportunities for materials to get misplaced or damaged. This results in a cleaner, safer, and more efficient job site.

Collaboration and Communication: Successful JIT requires constant communication between all parties involved—contractors, suppliers, and delivery teams. All parties must stay on the same page with the timeline and be informed of any changes in the project schedule.

Flexibility: JIT promotes adaptability. Construction projects are often subject to changes, and JIT allows for more flexibility when adjustments need to be made. If timelines shift or designs are altered, the project isn’t bogged down by excess inventory, making it easier to pivot as needed.

Utilizing JIT Delivery Strategies

Implementing JIT in construction requires careful planning and coordination between contractors, suppliers, and delivery teams. The key to successful JIT delivery is having a clear understanding of the project schedule and being able to predict when materials will be required.

One of the most important aspects of JIT delivery is communication. Contractors need to work closely with their suppliers to ensure materials can be delivered exactly when needed. This requires real-time updates on project progress and any adjustments to deadlines, as timing is crucial for JIT to work effectively. Additionally, keeping a reliable supply chain is essential, as any delays in delivery can disrupt the entire project.

JIT delivery strategies can be particularly beneficial for large-scale construction projects where space is limited and efficiency is key. It can also help in reducing material wastage, since ordering only what is necessary minimizes the risk of over-ordering or storing items that may get damaged on-site.

Benefits of Just-in-Time in Construction

Just-in-Time (JIT) offers several advantages in construction, especially when it comes to efficiency and cost savings. Here are some of the main advantages:

Reduced Storage Costs: One of the most significant benefits of JIT in construction is minimizing the need for on-site storage. With materials arriving just when they’re needed, there’s no need to pay for additional space or worry about inventory taking up valuable room on the job site. This is especially helpful on projects where space is tight.

Less Waste: Just-in-Time helps cut down on excess material waste by ensuring that only the necessary amount of resources is ordered. This reduces the risk of over-ordering and having materials go unused or damaged while waiting to be used. This approach is more eco-friendly, helping to reduce the project’s environmental footprint.

Better Cash Flow: By purchasing materials as needed rather than in bulk, construction companies can maintain a healthier cash flow. Instead of tying up capital in stockpiles of materials that may not be used right away, funds are available for other important aspects of the project, like labor and equipment.

Improved Project Efficiency: JIT promotes smoother project management. By having materials arrive precisely when they are required, the work can proceed without unnecessary delays, helping to keep the project on schedule. The streamlined process also reduces the likelihood of misplaced or damaged materials, keeping things more organized.

Increased Flexibility: Construction projects often deal with last-minute changes or design revisions. JIT makes it easier to adapt to these changes since you’re not stuck with excess inventory that doesn’t fit the updated plans. This flexibility allows the project to adapt without causing significant disruptions.

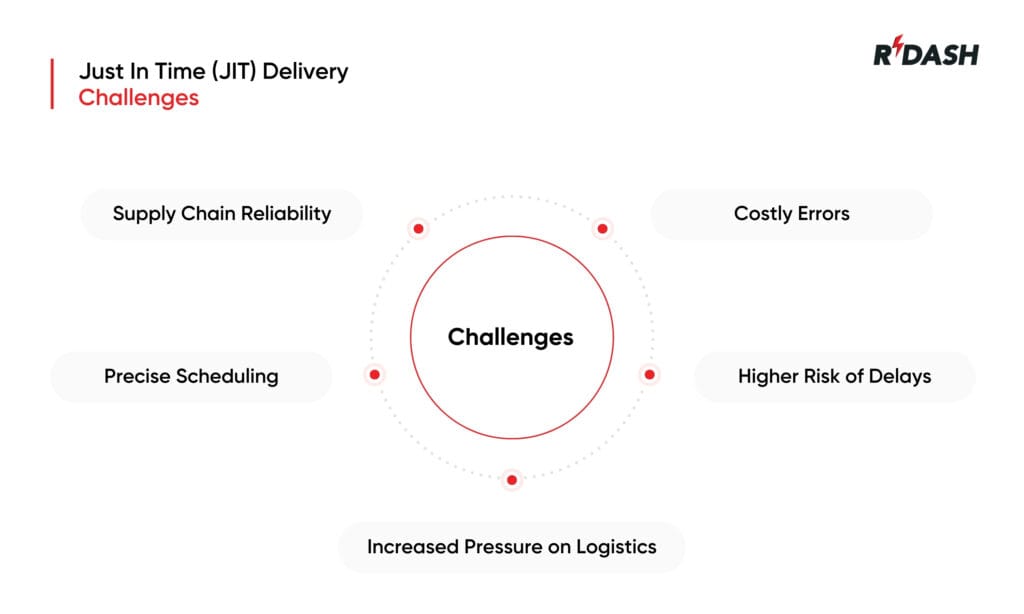

Challenges of Implementing Just-in-Time in Construction

While the benefits of JIT in construction are clear, it’s not without its challenges. Implementing this strategy requires careful planning and some potential hurdles to overcome:

Supply Chain Reliability: JIT depends heavily on reliable suppliers and delivery schedules. If there are any disruptions in the supply chain—such as delays from vendors, shipping issues, or material shortages—it can throw off the entire project timeline. A single delay can have a ripple effect, causing work stoppages and missed deadlines.

Precise Scheduling: For JIT to work, construction teams need to be extremely accurate with their scheduling. If materials arrive too early or too late, it can cause problems. Early deliveries may lead to the very issue JIT is designed to avoid—stockpiling. Late deliveries, on the other hand, can bring work to a standstill. Effective communication and coordination are essential to making sure materials arrive at the right time.

Increased Pressure on Logistics: Just-in-Time puts more pressure on transportation and logistics. Deliveries need to be perfectly timed, often to multiple locations on a single project. This requires detailed planning and coordination between the project managers and suppliers, which can add complexity and stress to the logistics process.

Higher Risk of Delays: Since there is little to no buffer in terms of inventory, any unexpected hiccup can cause significant delays. If there’s an issue with the supplier or if bad weather disrupts deliveries, the project could suffer from downtime. Just-in-Time offers efficiency, but it also increases the project’s vulnerability to unforeseen disruptions.

Costly Errors: Mistakes in ordering the right quantities can be costly. Since JIT involves ordering materials on an as-needed basis, an error in the order can delay the project and lead to emergency purchases, often at a premium cost. There’s little room for error, and small mistakes can lead to significant setbacks.