What Is inventory forecasting?

Inventory forecasting is a strategic process used by businesses across various industries to predict the inventory needs to meet future customer demand. It involves using historical sales data, market trends, and statistical algorithms to estimate the right amount of stock needed at any given time. This vital component of inventory management helps companies maintain the delicate balance between having enough inventory to meet customer needs without overstocking, which can tie up capital unnecessarily.

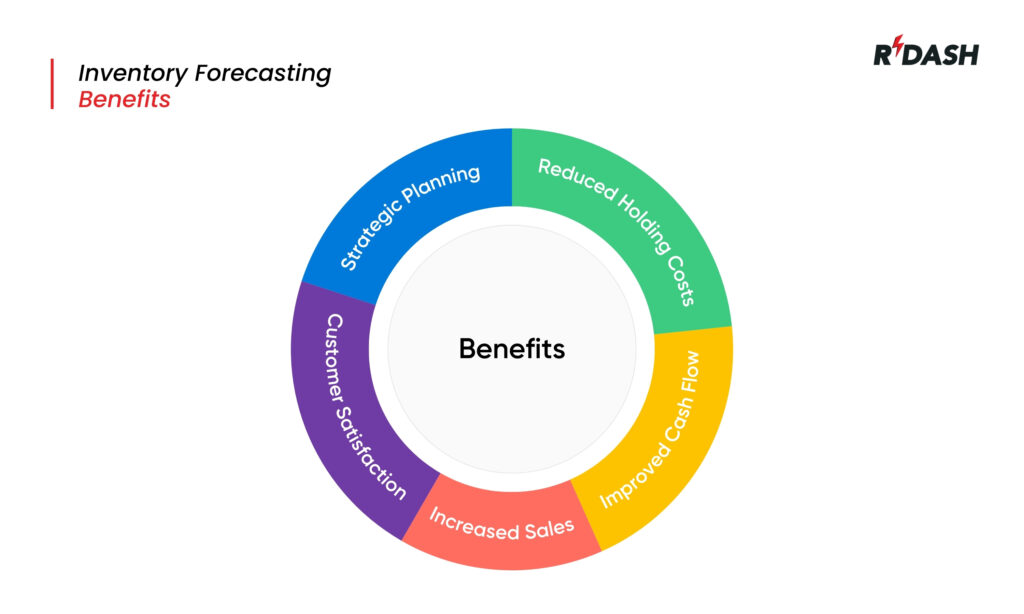

Benefits of inventory forecasting

Implementing inventory forecasting offers several significant benefits:

- Reduced Holding Costs: By accurately predicting inventory needs, businesses can avoid the costs associated with excess stock, such as storage fees, insurance, and the risk of obsolescence.

- Improved Cash Flow: Efficient inventory forecasting helps companies optimize their purchasing processes, which in turn improves cash flow. Money isn’t tied up in unused inventory, and can instead be invested back into the business or in new opportunities.

- Enhanced Customer Satisfaction: Having the right products available when customers need them is crucial for maintaining customer satisfaction and loyalty. Effective forecasting ensures that popular products do not run out of stock, helping to maintain consistent service levels.

- Increased Sales: With improved stock levels, businesses can avoid missed sales opportunities due to out-of-stock situations. Additionally, forecasting can identify potential sales increases, allowing businesses to stock up in anticipation of higher demand.

- Strategic Planning Support: Inventory forecasting plays a critical role in broader business planning. It provides valuable insights that can influence marketing strategies, budget allocations, and even expansion plans.

Types of inventory forecasting

There are several methods of inventory forecasting, each suited to different types of businesses and products:

- Qualitative Forecasting: This method is often used when there isn’t a lot of data available, such as with new products or when entering new markets. It relies on market research, expert opinions, and other qualitative data to predict inventory needs.

- Time Series Forecasting: One of the most common methods, this approach uses historical sales data to identify trends and patterns. Time series forecasting can be quite accurate for products with stable demand.

- Causal Forecasting: This type of forecasting considers external factors that could influence demand, such as economic conditions, marketing efforts, or seasonal changes. It’s particularly useful for businesses whose products are impacted by external trends.

- Multivariate Forecasting: A more complex form of forecasting, this method uses machine learning algorithms to analyze multiple variables at once. It’s suitable for large businesses with significant amounts of data and can be highly predictive.

- Exponential Smoothing: This approach smooths out data to predict future inventory needs, giving more weight to recent data points. It’s useful for businesses with fluctuating demand patterns.

- Moving Average: Simple yet effective, this method calculates the average of a fixed number of past periods to determine future needs. It’s easy to implement and is best used for products with minimal demand fluctuations.

How does inventory forecasting work?

Inventory forecasting operates on the principle of using historical data and analytical techniques to predict future inventory requirements. The process begins with data collection, where past sales figures, stock levels, and external factors influencing demand are gathered. This information is subsequently examined to pinpoint recurring patterns and trends. Techniques such as statistical analysis, machine learning models, or even simple moving averages are applied to project these patterns into the future. The outcome is a forecast that businesses use to determine how much stock to keep on hand at any given time, ensuring they are well-prepared to meet customer demand without overstocking.

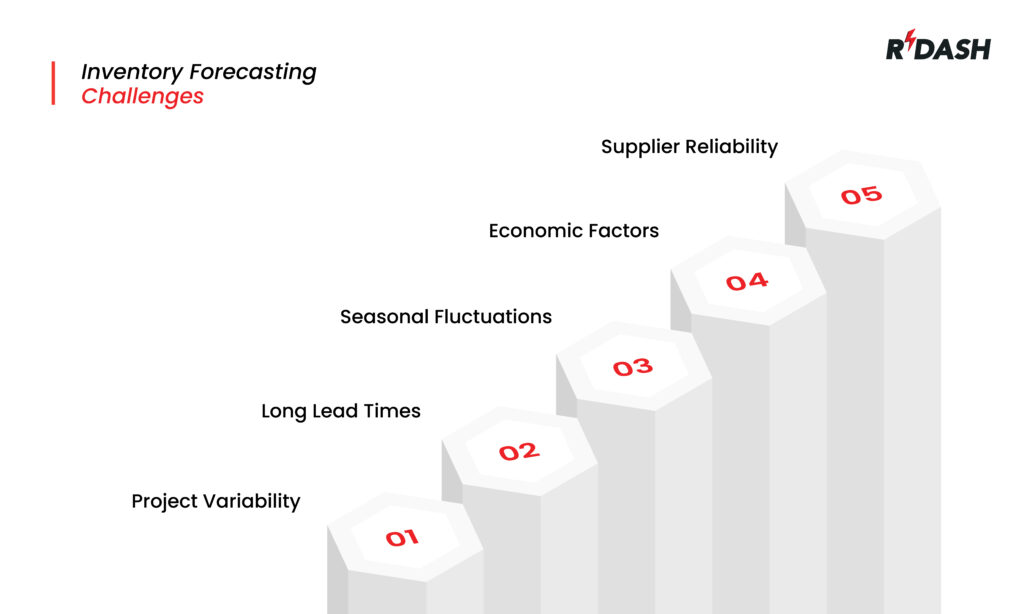

Common challenges in inventory forecasting for construction

Inventory forecasting in the construction industry comes with its unique set of challenges:

- Project Variability: Unlike retail environments where products are more standardized, construction projects can vary greatly, making it hard to predict inventory needs based on past projects alone.

- Long Lead Times: Many construction materials have long lead times, complicating the forecasting process. Delays in material delivery can have cascading effects on the entire project schedule.

- Seasonal Fluctuations: The construction industry is often subject to seasonal changes, with weather conditions impacting both the demand for materials and the pace of construction work.

- Economic Factors: Fluctuations in the economy can affect construction spending and investment, thereby influencing inventory needs unpredictably.

- Supplier Reliability: Relying on external suppliers adds a layer of uncertainty, as any disruptions in the supply chain can impact inventory availability.

How to choose the right forecasting method

Selecting the appropriate inventory forecasting method for a construction business involves several steps:

- Assess Data Availability: Look at the quantity and quality of historical data you have. Having access to a larger dataset enables the application of more sophisticated and precise forecasting techniques.

- Understand Demand Patterns: Analyze whether demand is stable, seasonal, or influenced by external factors. This understanding will guide you in choosing a method that best fits the demand pattern.

- Consider External Factors: Be aware of external factors such as economic conditions, industry trends, and supplier reliability that could influence inventory levels.

- Evaluate Forecasting Models: From simple models like moving averages to more complex ones involving exponential smoothing or even predictive analytics, evaluate which models align with your business’s capabilities and needs.

- Test and Refine: Implement the chosen method on a small scale to test its accuracy and refine it based on the outcomes. Forecasting is not a set-it-and-forget-it process but requires continuous adjustment and improvement.

- Training and Tools: Ensure that your team is trained in using the selected forecasting tools effectively, and invest in technology that can automate and aid in more accurate forecasts.

By carefully navigating these steps, construction businesses can enhance their inventory management practices, ensuring they efficiently meet project demands while minimizing waste and costs. This tailored approach to inventory forecasting not only supports operational efficiency but also contributes to overall project success.

Improve inventory tracking with RDash

Inventory forecasting is vital for the success of construction projects. It allows for better resource allocation, minimizes waste, and ensures projects are completed on time and within budget. Utilize RDash to improve your inventory management practices, reduce project setbacks, and ultimately secure greater success in your construction endeavors.