In the construction industry, Supplier Onboarding is a critical process that determines the quality and reliability of materials, services, and the overall success of a project. Given the complexity and scale of construction projects, especially in India, where diverse suppliers are engaged, effective due diligence becomes paramount. Supplier onboarding is not just about selecting a vendor; it’s about ensuring that each supplier aligns with your business goals, complies with legal standards, and provides quality products or services consistently.

This blog explores the importance of effective due diligence during supplier onboarding, particularly in the Indian construction industry, and outlines a comprehensive strategy to onboard suppliers efficiently. Additionally, we’ll introduce RDash, a construction management app that streamlines supplier onboarding and other crucial project management tasks.

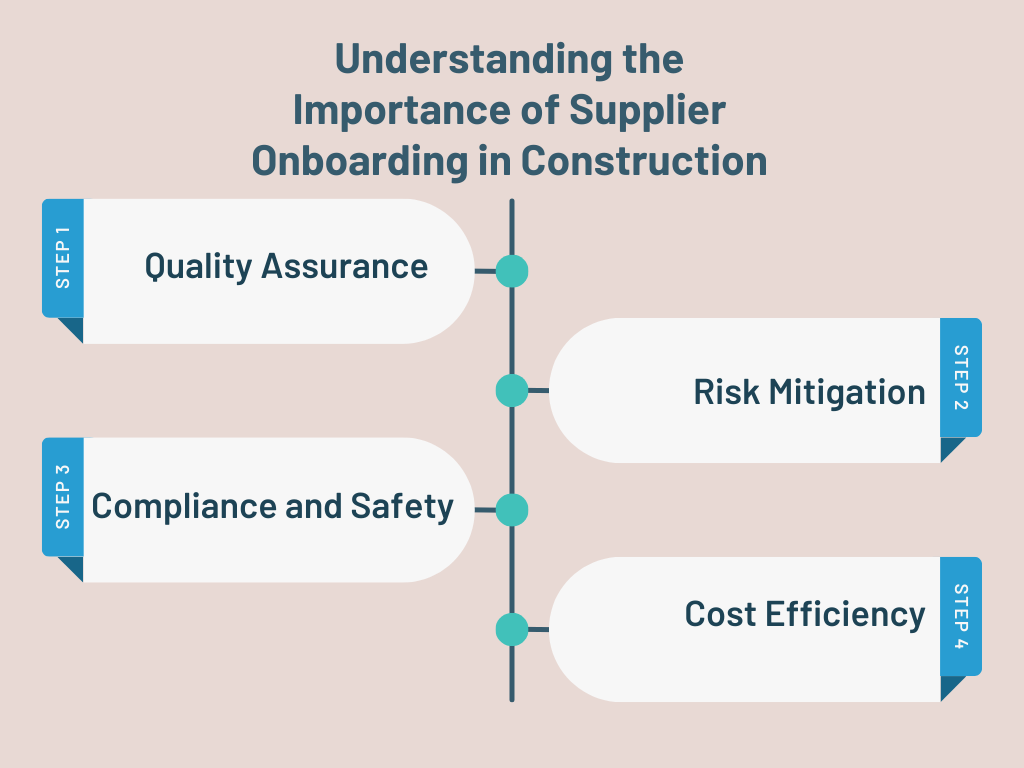

Understanding the Importance of Supplier Onboarding in Construction

Supplier onboarding in construction is the process of integrating new suppliers into the company’s supply chain, ensuring that they meet the required standards for quality, safety, and compliance. In the context of the Indian construction sector, where the market is highly fragmented with numerous small-scale suppliers, effective onboarding is vital for several reasons:

- Quality Assurance: Ensures the supply of high-quality materials and services.

- Risk Mitigation: Reduces the risk of project delays or cost overruns due to unreliable suppliers.

- Compliance and Safety: Ensures adherence to legal, environmental, and safety regulations.

- Cost Efficiency: Streamlines procurement processes and fosters long-term relationships with reliable suppliers.

Effective onboarding can enhance project outcomes by establishing a robust supply chain that supports the timely delivery of quality construction projects.

The Challenges of Supplier Onboarding in the Indian Construction Sector

Supplier onboarding in India poses unique challenges due to the country’s diverse and complex construction landscape. Some of the common challenges include:

- Fragmented Supplier Base: The Indian construction industry comprises many small and medium enterprises (SMEs) with varying standards.

- Regulatory Compliance: Navigating the myriad of local, state, and national regulations can be challenging, particularly for small suppliers.

- Quality Control Issues: Ensuring consistent quality from suppliers who may not have standardized processes.

- Cultural and Communication Barriers: Differences in language, business practices, and cultural norms can create misunderstandings and inefficiencies.

To address these challenges, construction companies must implement a structured due diligence process during supplier onboarding.

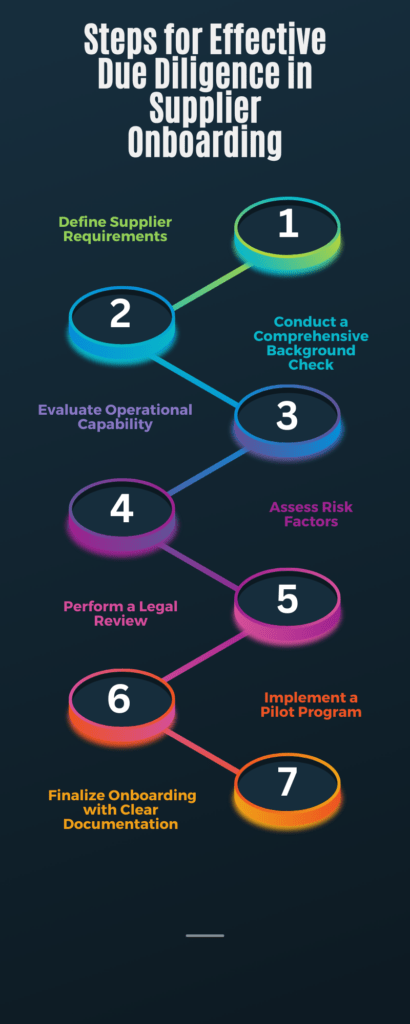

Steps for Effective Due Diligence in Supplier Onboarding

Effective due diligence is the backbone of successful supplier onboarding. Here are the essential steps involved in conducting due diligence:

Step 1: Define Supplier Requirements

Before initiating the onboarding process, clearly define your supplier requirements based on project needs. This includes:

- Quality Standards: Specify the quality of materials or services required.

- Compliance: Outline necessary regulatory, environmental, and safety standards.

- Capacity and Capability: Assess the supplier’s ability to meet your volume and delivery timelines.

- Financial Stability: Ensure suppliers are financially sound to avoid potential disruptions.

Step 2: Conduct a Comprehensive Background Check

A thorough background check is crucial to verify the supplier’s credibility. This should include:

- Reputation Check: Investigate the supplier’s market reputation through references, past clients, and industry reviews.

- Financial Health: Evaluate financial statements, credit ratings, and banking references to ensure financial stability.

- Compliance Verification: Confirm that the supplier complies with local and national regulations, including labor laws, environmental policies, and safety standards.

- Certifications and Accreditations: Verify relevant certifications (e.g., ISO standards) and industry accreditations.

Step 3: Evaluate Operational Capability

Assess the supplier’s operational capabilities to ensure they can meet your project’s requirements. This involves:

- Site Visits: Conduct on-site inspections to evaluate the supplier’s facilities, equipment, and production processes.

- Capacity Assessment: Determine if the supplier has the capacity to deliver the required volume of goods or services.

- Quality Management Systems: Review the supplier’s quality control procedures and management systems.

- Supply Chain Robustness: Analyze the supplier’s supply chain to ensure reliability and minimal disruptions.

Step 4: Assess Risk Factors

Risk assessment is a critical component of due diligence. Identify and evaluate potential risks, including:

- Financial Risks: Risks related to the supplier’s financial instability or insolvency.

- Operational Risks: Risks due to the supplier’s production capacity, quality control issues, or supply chain vulnerabilities.

- Compliance Risks: Risks related to non-compliance with legal and regulatory standards.

- Reputational Risks: Risks associated with the supplier’s market reputation or past performance.

Step 5: Perform a Legal Review

Conduct a legal review to identify any legal risks or liabilities associated with the supplier. This includes:

- Contract Review: Ensure that all contracts are clear, enforceable, and protect your interests.

- Legal Compliance: Verify that the supplier complies with all relevant laws and regulations, including tax laws, labor laws, and environmental regulations.

- Intellectual Property: Ensure there are no intellectual property infringements or disputes.

Step 6: Implement a Pilot Program

Before fully onboarding a supplier, implement a pilot program to test their performance on a smaller scale. This helps in:

- Evaluating Performance: Assess the supplier’s ability to meet quality standards, delivery timelines, and compliance requirements.

- Identifying Issues: Identify any issues or challenges early in the process.

- Building Relationships: Develop a working relationship with the supplier and establish clear communication channels.

Step 7: Finalize Onboarding with Clear Documentation

Once a supplier has passed all due diligence checks, finalize the onboarding process with comprehensive documentation:

- Supplier Agreements: Draft detailed agreements outlining terms, conditions, quality standards, delivery schedules, and penalties for non-compliance.

- Service Level Agreements (SLAs): Establish SLAs to define performance expectations and metrics.

- Compliance Documentation: Ensure all compliance-related documents are signed and filed.

- Training and Orientation: Provide training and orientation to the supplier on your company’s policies, procedures, and expectations.

Best Practices for Supplier Onboarding in Construction

To enhance supplier onboarding and due diligence processes, construction companies should adopt the following best practices:

- Develop a Centralized Supplier Database: Maintain a centralized database of all approved suppliers, including relevant documentation and performance history.

- Implement Supplier Performance Monitoring: Continuously monitor supplier performance through regular audits, inspections, and feedback mechanisms.

- Leverage Technology: Use digital tools and software to streamline the onboarding process, manage supplier data, and enhance communication.

- Engage in Collaborative Partnerships: Foster long-term, collaborative partnerships with suppliers to build trust and improve performance.

- Promote Transparency and Communication: Ensure open communication channels with suppliers to address issues promptly and maintain strong relationships.

The Role of Technology in Supplier Onboarding

Technology plays a vital role in enhancing the supplier onboarding process. In the construction industry, digital tools can be leveraged to:

- Automate the Onboarding Process: Use software solutions to automate the onboarding process, reducing administrative burdens and speeding up approval times.

- Enhance Data Management: Utilize cloud-based platforms to store, manage, and access supplier data securely.

- Improve Communication: Implement digital communication tools to enhance collaboration with suppliers and streamline processes.

- Facilitate Compliance: Use compliance management software to ensure suppliers adhere to all regulatory requirements.

- Monitor Performance: Deploy supplier performance management tools to track and evaluate supplier performance over time.

By integrating technology into the onboarding process, construction companies can improve efficiency, reduce risks, and enhance supplier relationships.

The Golden Journey of a Project with RDash

To further streamline supplier onboarding and other key aspects of project management, RDash—a comprehensive construction management app—offers a suite of tools tailored for the construction industry. RDash guides project managers through the Golden Journey of a project, which includes:

- Recce: Conducting site surveys and initial assessments to gather crucial information about the project site.

- Design: Collaborating with designers to develop detailed plans that meet client expectations and regulatory standards.

- BOQ (Bill of Quantities): Preparing and managing BOQs to outline the materials, labor, and services required for the project.

- Order: Streamlining the ordering process to ensure timely procurement of materials and services.

- Work Progress: Monitoring work progress in real time to ensure projects stay on schedule and within budget.

- Snags: Identifying and addressing defects or issues quickly to maintain quality standards.

- Financial Closure: Managing financial aspects, including payments and cost reconciliations, to ensure the project is financially viable.

- Project Manager (PM) Task List: Providing a clear and comprehensive task list for project managers to enhance efficiency and accountability.

By leveraging RDash, construction companies can automate and optimize supplier onboarding, improve communication, enhance compliance, and ensure seamless project execution from start to finish.

Case Studies: Successful Supplier Onboarding in Indian Construction

Several Indian construction companies have successfully implemented effective supplier onboarding processes:

- Case Study 1: Tata Projects Limited

Tata Projects Limited, a leading construction company in India, has implemented a robust supplier onboarding and due diligence process. By leveraging technology and adopting a risk-based approach to supplier selection, the company has minimized risks and ensured the consistent supply of quality materials.

- Case Study 2: Larsen & Toubro (L&T)

L&T has developed a comprehensive supplier onboarding framework that includes stringent quality checks, site visits, and financial assessments. The company’s focus on long-term partnerships and collaboration has enhanced supplier performance and project outcomes.

These case studies demonstrate the importance of effective due diligence and strategic supplier onboarding in achieving successful project outcomes.

Conclusion

Supplier onboarding with effective due diligence is essential for the success of construction projects in India. By adopting a structured approach, conducting thorough due diligence, and leveraging technology, construction companies can mitigate risks, ensure quality, and build strong supplier relationships. RDash, with its comprehensive construction management tools, can further enhance the onboarding process, making it more efficient and effective. By implementing these strategies and utilizing modern tools, construction companies in India can achieve better project outcomes and drive growth in a competitive market.