In the construction world, turning a blueprint into a real, standing structure requires more than just drawings and measurements. It requires clear communication, detailed planning, and strict adherence to quality standards. That’s where construction specifications come into play.

Construction specifications – often simply called specs – are the backbone of a project. They define how work should be done, what materials should be used, and the quality expectations for each stage of construction. Without proper specifications, even the best-designed projects can face confusion, delays, cost overruns, or safety risks.

In this blog, we’ll explore what construction specifications are, their different types, and why they’re so critical to every successful construction project.

What are construction specifications?

Construction specifications are detailed documents that explain the materials to be used, how the work should be done, the quality standards to follow, and how everything will be tested in a construction project.

Think of them as the manual that explains how to build what is shown in the architectural and engineering drawings.

While drawings tell you what to build, specifications tell you how to build it.

These documents are typically prepared by architects, engineers, or consultants during the planning phase of the project and are shared with all stakeholders – clients, contractors, vendors, and site teams.

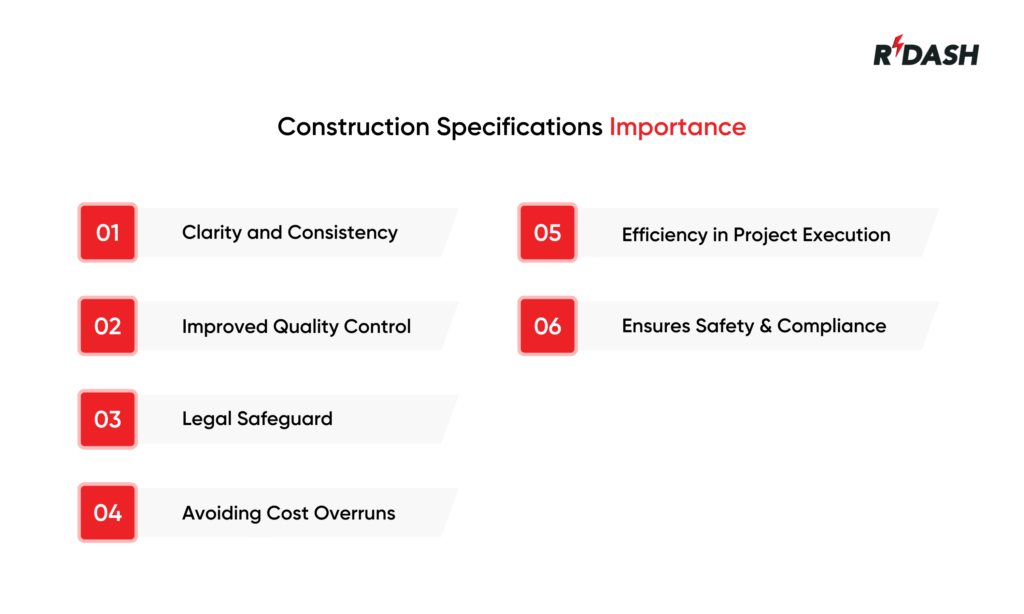

Why are construction specifications important?

1. Clarity and Consistency

They help avoid confusion by clearly outlining what is expected at each stage of the construction process. Everyone involved knows exactly what is required, which helps keep the work consistent and aligned with the design intent.

2. Improved Quality Control

By outlining standards and inspection requirements, specifications help ensure that the quality of materials and workmanship meets the agreed-upon benchmarks.

3. Legal Safeguard

Construction specifications are part of the contract between the client and contractor. In case of disputes or claims, specs serve as a reference point to determine who is responsible for any deviations.

4. Avoiding Cost Overruns

Without clear construction specifications, contractors may make assumptions or use cheaper materials, which could lead to poor results and costly rework. Detailed specifications help avoid these problems by setting clear expectations from the beginning.

5. Efficiency in Project Execution

Well-written specs streamline procurement, scheduling, and on-site execution. They help contractors plan their work better, avoid delays, and coordinate efficiently with vendors and subcontractors.

6. Ensures Safety and Compliance

Construction specs often include safety standards and references to local or international building codes. This ensures that the construction is not only high-quality but also safe and compliant with regulations.

Who should manage construction specifications?

Managing construction specifications is not a one-person job. It’s a collaborative effort between different professionals depending on the stage of the project and the area of work. Here’s who usually takes care of it:

1. Architects

Architects are generally responsible for writing and managing specifications that deal with design details, materials, and finishes. They make sure the specs align with the drawings and overall design plan.

2. Engineers

Structural, electrical, mechanical, and plumbing engineers are responsible for technical specifications in their respective areas. They define the materials, safety standards, and performance requirements for systems like wiring, piping, or HVAC.

3. Project Managers

Project managers oversee the entire process. They make sure that the specifications are clear, up to date, and shared with everyone—contractors, vendors, and site teams. They also ensure that the work being done follows these specs.

4. Contractors and Site Teams

While they don’t usually write specifications, contractors must read and follow them closely. If something is unclear, they often coordinate with the architects or engineers to clarify things before moving ahead.

Types of specifications in construction

Prescriptive Specifications

Prescriptive specifications describe exactly which materials, products, and installation methods must be used in the project. They include detailed instructions about how the work should be carried out. These specifications often mention brand names, sizes, finishes, and even the technique to be used. They may also refer to local or international quality standards.

This type of specification is helpful when the project requires full control over quality and consistency. Because everything is clearly written, there is less chance of mistakes or misunderstandings. However, it gives little freedom to contractors, as they must follow the instructions exactly as written.

Performance Specifications

Performance specifications describe what the final outcome should be, without giving exact instructions on how to reach that result. Instead of giving fixed instructions, they describe the expected outcome, such as strength, durability, or energy efficiency.

This approach gives contractors the freedom to choose materials and construction methods, as long as the final result meets the project’s requirements. It encourages creative and cost-effective solutions, especially when time or budget is tight. However, these specifications must be carefully monitored to ensure the quality of the final result.

Proprietary Specifications

Proprietary specifications require the use of a specific product, brand, or system. These specifications are used when a particular item is necessary to meet the design, function, or warranty requirements of the project. In some cases, substitutions are allowed if they meet similar standards, but often only the listed product can be used.

This type of specification is common when the designer or client wants to maintain a certain look, feel, or technical feature across the project. While this brings uniformity, it may limit contractor options and increase costs if the specified item is expensive or hard to source.

Choosing the Right Specifications

Choosing the right type of specification depends on the project’s goals, budget, flexibility, and timeline. If the focus is on control and precision, prescriptive specifications are ideal. If flexibility and innovation are important, performance specifications are a better choice. And if a specific product is essential for design or function, proprietary specifications are the way to go.

Often, projects use a mix of all three types. For example, structural work may require prescriptive specs, while decorative finishes may follow proprietary specs. The key is to use each type where it fits best.

How construction specifications are created

Construction specifications are usually written by architects, engineers, or consultants during the planning phase of a project. They work closely with clients, designers, and technical experts to make sure all details are correct.

Here’s how the process generally works:

- Understanding the Project Needs

The first step is to understand what the project is about—its size, purpose, design, and budget. The team gathers details from drawings and client requirements. - Listing Materials and Work Methods

The team then writes down what materials should be used and how each activity (like painting, wiring, or flooring) should be done. They also mention the quality standards that must be followed. - Following Codes and Regulations

Specifications must meet local and national building codes. Any safety, environmental, or legal requirements are added here. - Organizing by Sections or Divisions

To make specs easier to read and follow, they are divided into sections like civil work, electrical work, plumbing, finishes, etc. Each section covers the scope of work, materials, workmanship, and testing methods. - Review and Finalization

The draft specifications are reviewed by the project team, and once approved, they are shared with contractors and vendors as part of the contract documents.

How can construction specifications be improved?

Even though construction specifications are essential, they are often long, confusing, or too technical. This can lead to errors during execution. Here are some ways they can be improved:

1. Use Simple, Clear Language

Avoid overly technical or complicated terms unless necessary. Specs should be easy for everyone – site teams, contractors, and vendors – to understand and follow.

2. Update Regularly

Projects evolve, and specs should too. If any design or material change is made, the specifications must be updated immediately to avoid confusion later.

3. Include Visuals Where Needed

Where possible, use diagrams, charts, or sample images to explain important details. It helps the team clearly understand their responsibilities and what needs to be delivered.

4. Align with Drawings and BOQ

Make sure that the specifications match the design drawings and the bill of quantities. Any mismatch can lead to errors, extra costs, or rework on site.

5. Mention Testing and Quality Checks

The construction specifications must clearly explain the methods for checking the quality of materials and work done. This helps maintain quality and sets the right expectations for the site team.

6. Use Digital Tools

Instead of relying only on printed documents, use digital platforms to create, share, and manage specifications. It improves teamwork and ensures all stakeholders are working with the most up-to-date information.

7. Involve Contractors Early

Contractors often bring practical experience that can help improve specs. Involving them early in the planning process can lead to better material choices and more realistic execution plans.