What is Construction Rework?

Construction rework means doing a part of the project again because it was done incorrectly the first time. This could include fixing a wall that was built in the wrong place, changing electrical wiring that doesn’t meet the plan, or redoing a floor because the wrong material was used.

Construction rework happens when a task does not meet the required standards or the approved design and needs to be corrected. It often leads to delays, added costs, and frustration for both the contractor and the client. Even a small rework can affect the overall timeline of the project.

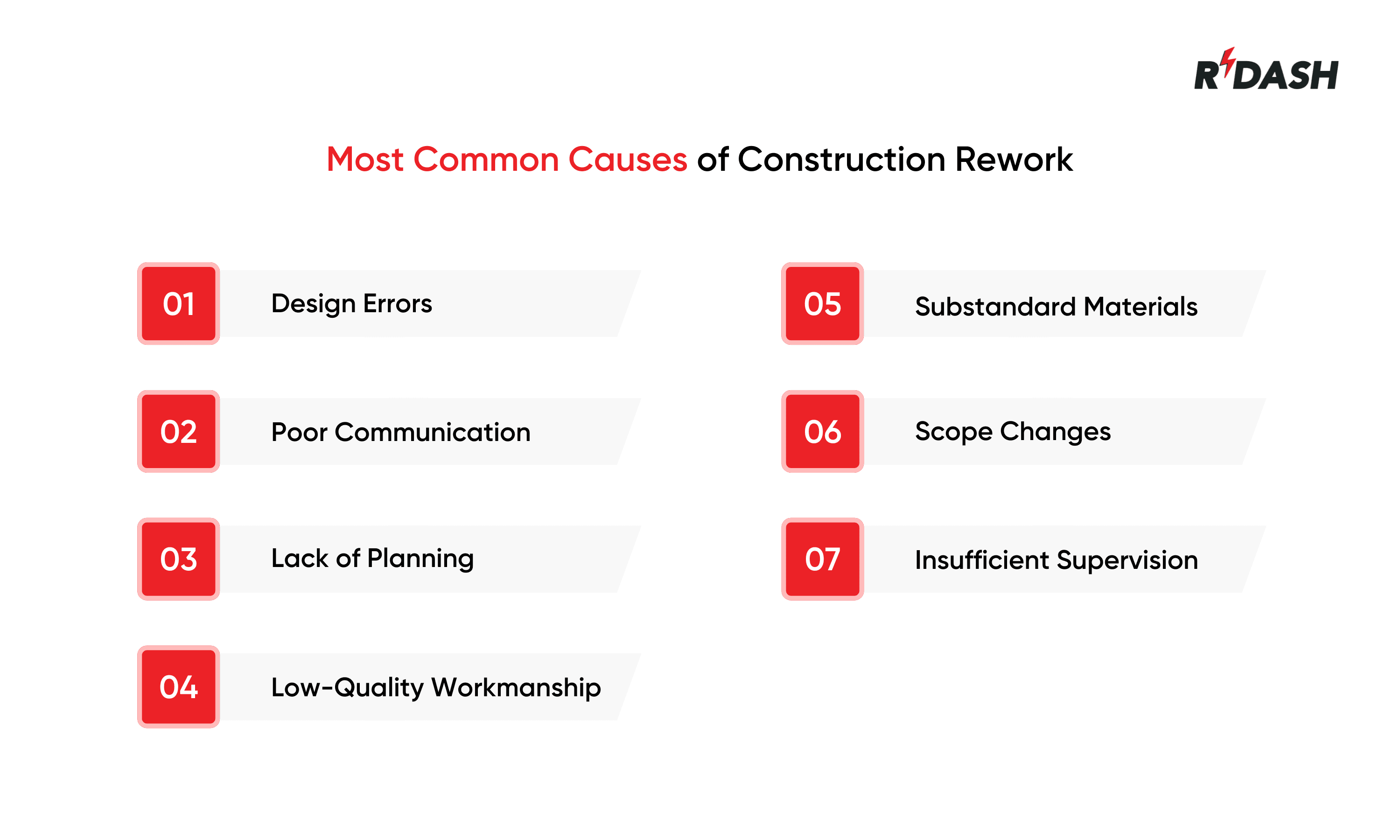

What are the most common causes of construction rework?

Construction rework can be frustrating, expensive, and time-consuming. Understanding the root causes can help teams avoid mistakes and keep the project on track. Below are the most common reasons why rework happens on construction sites:

1. Design Errors or Incomplete Drawings

One of the biggest reasons for rework is poor or incomplete design. If the architectural or engineering plans are unclear, outdated, or have mistakes, the construction team may build something incorrectly. This leads to tearing down and redoing the work once the error is discovered.

2. Poor Communication Between Teams

In construction, many teams are involved—architects, engineers, contractors, subcontractors, and suppliers. If there is miscommunication or missing information between any of these groups, tasks may be carried out incorrectly, resulting in rework.

3. Lack of Planning or Coordination

When tasks are not properly scheduled or roles are not clearly defined, it increases the chances of mistakes. Rushed work or overlapping activities can lead to conflicts and errors, especially on large or fast-paced projects.

4. Low-Quality Workmanship

If the workers are not skilled enough or proper construction practices are not followed, the final output may not meet the required standards. In such cases, the work needs to be redone to ensure safety and quality.

5. Use of Incorrect or Substandard Materials

Sometimes, wrong or low-grade materials are used, either due to errors in delivery, cost-cutting, or oversight. These materials may fail quality tests or not match the approved specifications, which requires replacing or reworking them.

6. Late Design or Scope Changes

Clients or designers may request changes after the construction has already begun. These changes often affect work that’s already done, requiring demolition or major corrections.

7. Insufficient Supervision and Quality Checks

If site supervisors are not actively checking the work in progress, small issues can go unnoticed. By the time they are caught, the affected area may need to be rebuilt, leading to major rework.

What are the impacts of construction rework?

Construction rework doesn’t just mean doing a job twice; it affects the entire project in several ways. Below are the most common and serious impacts of rework:

1. Increased Project Costs

Rework adds extra expenses that weren’t planned. These include costs for labor, materials, equipment usage, and sometimes penalties or claims. Even minor fixes can turn into major budget issues when added up across multiple tasks.

2. Delays in the Project Timeline

Rework takes time, and time is money in construction. When workers have to redo tasks, it pushes the schedule back, leading to delays in future activities and possibly missing deadlines.

3. Poor Client Satisfaction

Frequent errors and delays can cause frustration for the client. It may hurt your company’s reputation and reduce the chances of winning future work from the same client or referrals.

4. Reduced Team Morale

Having to redo completed work can be demotivating for the workers. It creates frustration, stress, and may even lead to blame between teams. This can impact overall productivity and teamwork.

5. Material Waste

Rework often leads to discarded materials that cannot be reused. This increases waste at the site and affects sustainability goals. It may also lead to additional disposal costs.

6. Safety Risks

When work is rushed or torn down and rebuilt, there are more chances of accidents. Rework increases the number of site activities, which in turn raises the risk of injuries or safety incidents.

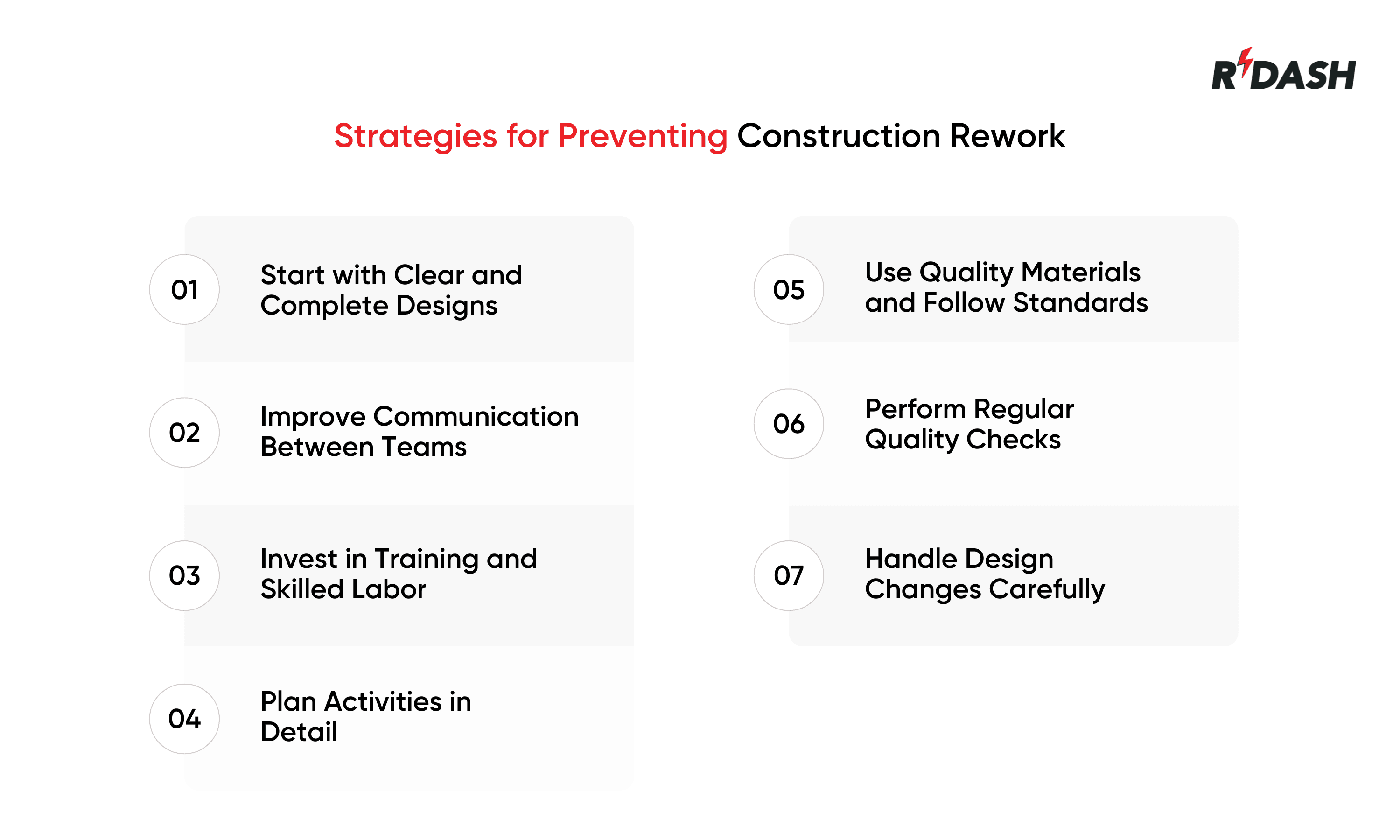

Strategies for preventing construction rework

Construction rework not only increases costs but also slows down progress and impacts team morale. While it may not be possible to avoid every mistake, there are proven strategies that can help reduce rework and keep your project running smoothly.

1. Start with Clear and Complete Designs

Before construction begins, make sure that the architectural and engineering drawings are detailed, accurate, and thoroughly reviewed. Involving all stakeholders early in the design stage helps catch potential issues before work starts on site.

2. Improve Communication Between Teams

A major cause of rework is miscommunication. Ensure all teams—designers, contractors, consultants, and suppliers – have access to the same information. Regular meetings and updates help align everyone and reduce confusion.

3. Invest in Training and Skilled Labor

Workers who are trained and experienced are less likely to make mistakes. Investing in the right team and providing them with clear instructions improves the quality of work and reduces the chances of errors.

4. Plan Activities in Detail

Proper planning means having clear timelines, assigning roles, and ensuring all materials and approvals are ready on time. This avoids rushed work, missed steps, and overlapping tasks that often lead to rework.

5. Use Quality Materials and Follow Standards

Using approved, high-quality materials and following proper construction methods helps ensure that work meets expected standards from the start, reducing the need for corrections later.

6. Perform Regular Quality Checks

Supervisors should carry out inspections during each stage of construction, not just at the end. Catching mistakes early means they can be fixed before they become major issues.

7. Handle Design Changes Carefully

If a client or architect requests changes during construction, assess the impact fully before proceeding. Make sure changes are documented, approved, and communicated clearly to everyone involved.

Rework less with RDash

RDash is designed to help construction teams avoid rework through better planning, clear communication, and real-time tracking. Here’s how RDash supports rework reduction:

Centralized Communication

RDash brings all project discussions, updates, and approvals into one shared platform. This eliminates the risk of miscommunication across teams and ensures that everyone is working with the latest information.

Document Management

With RDash, all drawings, change orders, and specifications are stored in one place. Team members can easily access the latest version of any document, which reduces mistakes caused by outdated or missing files.

DPR (Daily Progress Reports)

Generate DPRs with a single click using RDash. Regular updates help identify small issues early, before they grow into larger problems that require rework.