What is Construction Resource Management?

Construction resource management involves planning, assigning, and tracking all the resources required to successfully complete a construction project. These resources cover both human and non-human aspects, including workforce, materials, machinery, and technology. Proper resource management ensures availability at the right time, in the right amount, and at an optimal cost.

Good resource management improves project efficiency, reduces waste, and helps projects finish on schedule and within budget. Without it, construction teams may face delays, cost overruns, and resource shortages that can harm productivity and client satisfaction.

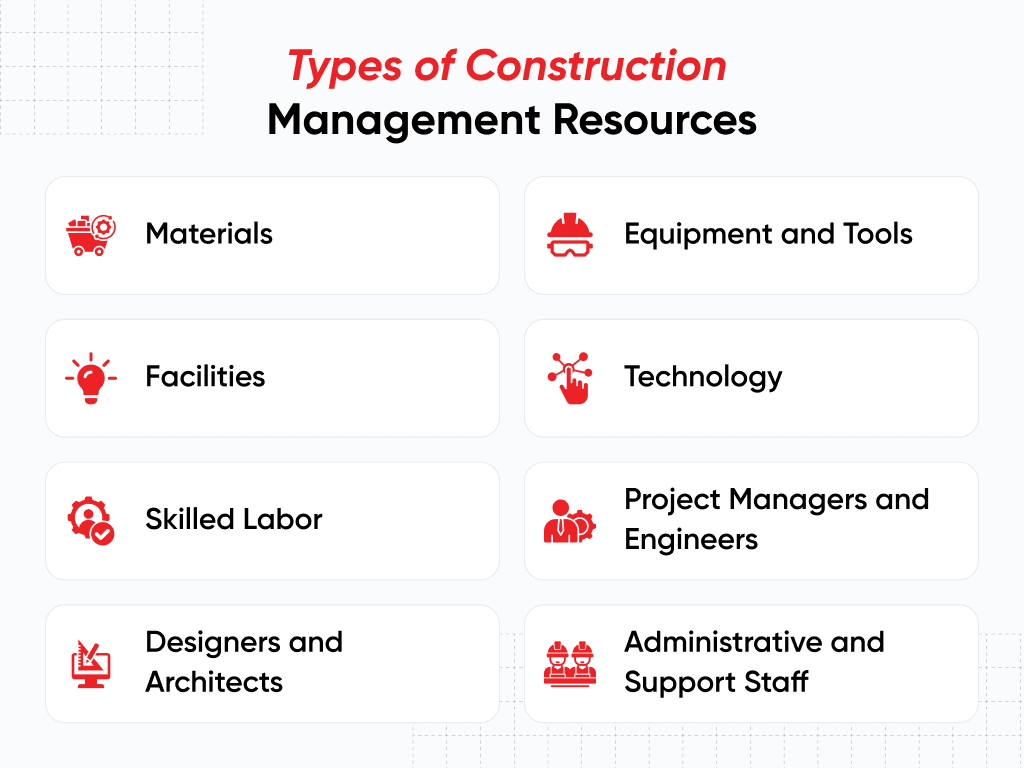

Types of Construction Management Resources

In construction, resources generally fall into two categories: human resources and non-human resources.

Non-human Resources

Non-human resources refer to all the physical and digital assets used in construction projects. These can include:

- Materials – Items like cement, steel, bricks, tiles, and other supplies needed to build. Maintaining a consistent supply helps avoid delays and supports high-quality work.

- Equipment and Tools – Machinery such as excavators, cranes, concrete mixers, power tools, and safety gear. Proper maintenance and timely availability keep projects running smoothly.

- Technology – Software for project scheduling like RDash, budgeting, and communication, as well as digital tools like Building Information Modeling (BIM). Technology speeds up planning and coordination.

- Facilities – On-site offices, storage areas, and warehouses where work is managed and materials are stored.

Human Resources

Human resources refer to the individuals responsible for planning, supervising, and carrying out the project work. They can be divided into:

- Skilled Labor – Workers like carpenters, masons, welders, electricians, and plumbers who perform specialized tasks.

- Project Managers and Engineers – Professionals who oversee the project, plan schedules, allocate resources, and ensure quality standards are met.

- Designers and Architects – Experts who create the building plans and ensure the design meets both functional and aesthetic goals.

- Administrative and Support Staff – Personnel who handle documentation, procurement, payroll, and other back-office activities.

Types of Construction Resource Management

Construction resource management can be broadly divided into two main types – strategic and operational. Both human and non-human resources play a vital role in keeping projects on schedule and achieving maximum efficiency.

Strategic Construction Resource Management

This focuses on long-term planning and decision-making. It involves determining how resources will be used across multiple projects or over an extended period. Strategic resource management ensures that the right materials, labor, and equipment are available when needed, without causing delays or overspending. It also helps forecast demand, manage supplier relationships, and maintain an adequate workforce.

Operational Construction Resource Management

This is about day-to-day resource allocation and monitoring. Efficient resource use during the execution phase is essential for smooth project progress. Operational management involves scheduling workers, tracking equipment usage, and making adjustments when issues arise on-site. It’s the hands-on approach that keeps the project running smoothly and according to plan.

Construction Resource Management Process

A well-organized approach ensures that resources are managed effectively from start to finish.

1. Conduct a Material Takeoff Analysis for Your Project

This step involves creating a detailed list of all required materials and their quantities. A material takeoff helps prevent shortages or excess ordering, ensuring that procurement is timely and cost-effective.

2. Write a Scope of Work

The scope of work outlines the project’s deliverables, specific tasks, timelines, and assigned responsibilities in detail. It acts as a guide for everyone involved and prevents confusion later.

3. Estimate Costs

Preparing an accurate cost estimate helps prevent budget overruns. This involves calculating wages, material costs, and expenses related to renting or purchasing equipment.

4. Create a Construction Budget

Using the cost estimates, develop a budget that covers all project phases. A clear budget helps track expenses and identify cost-saving opportunities.

5. Acquire Resources and Start Project Work

Once the plan and budget are in place, procure the required resources and begin work on-site. Timely acquisition is critical to avoid delays.

6. Distribute Resources and Oversee Utilization

Distribute the right workforce, materials, and equipment to each task. Continuously track their usage to maintain efficiency and reduce unnecessary waste.

7. Track Expenses and Maintain the Project Budget

Keep a real-time record of all expenses and compare them with the budget. This enables quick action if costs begin to rise, ensuring the project remains financially on track.

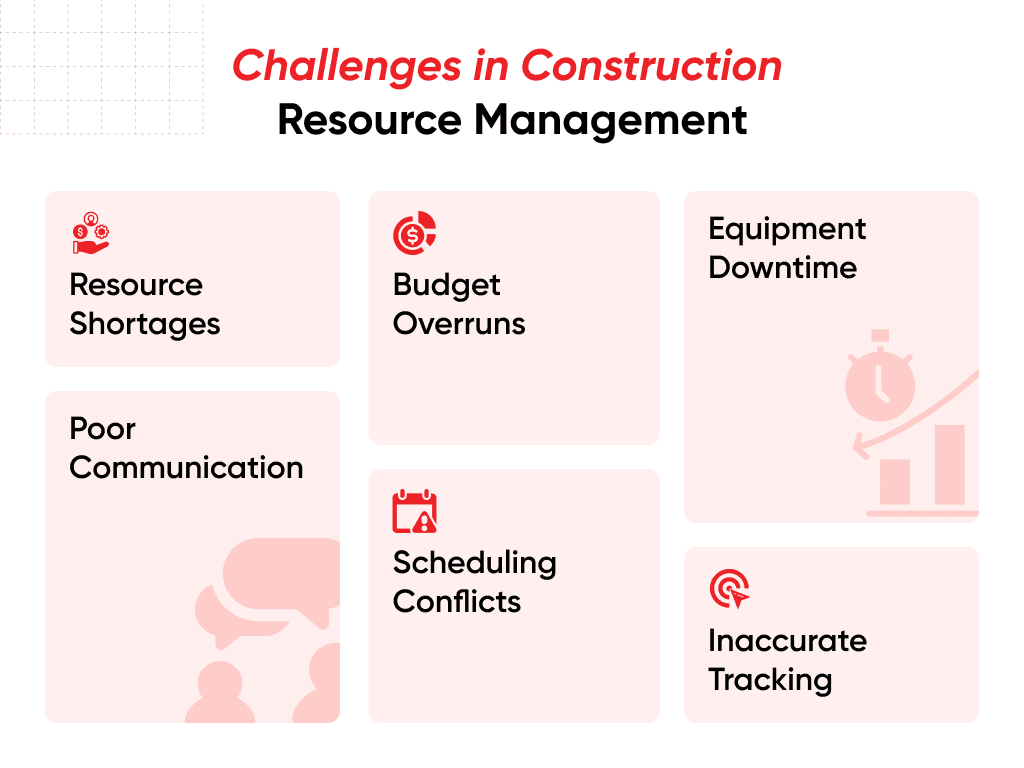

Challenges in Construction Resource Management

Managing resources in construction is not always straightforward. Even the best plans can face obstacles that affect timelines, costs, and quality.

1. Resource Shortages

Finding skilled labor or sourcing specific materials on time can be challenging, especially during peak construction seasons or supply chain disruptions.

2. Budget Overruns

Without close monitoring, costs for labor, equipment, and materials can quickly exceed the planned budget, affecting overall profitability.

3. Poor Communication

Miscommunication between teams can result in resource misallocation, delays, or duplicate efforts.

4. Scheduling Conflicts

When multiple projects are running simultaneously, resource schedules may overlap, causing bottlenecks and idle time.

5. Equipment Downtime

Breakdowns or maintenance issues with machinery can cause unexpected delays and require expensive repairs.

6. Inaccurate Tracking

Without proper tracking tools, it’s hard to know how resources are being used, leading to inefficiency and wastage.

Best Practices for Effective Construction Resource Management

To overcome these challenges, construction companies can follow proven strategies that make resource management smoother and more efficient.

Use Construction Management Software

Digital tools like RDash help monitor resources in real time, streamline communication, and prevent costly errors.

Plan Ahead

Create detailed schedules for labor, materials, and equipment well before the project starts. This reduces the risk of last-minute shortages.

Monitor and Adjust Regularly

Monitor how resources are being used during the project and adjust as necessary to maintain both the timeline and the budget.

Maintain Good Supplier Relationships

Strong relationships with reliable suppliers can help secure materials quickly and at better rates.

Train Your Team

Well-trained staff can use resources more effectively, follow safety protocols, and adapt to unexpected changes more easily.

Keep a Contingency Plan

Always have backup resources or alternate suppliers in case of emergencies or sudden shortages.