Vendor selection is the process of choosing the best supplier or service provider for a specific job, project, or service. It involves evaluating potential vendors based on criteria like price, quality, reliability, and service to ensure you’re partnering with the right company for your needs. This process is crucial in helping businesses cut costs, boost efficiency, and maintain high standards across their operations.

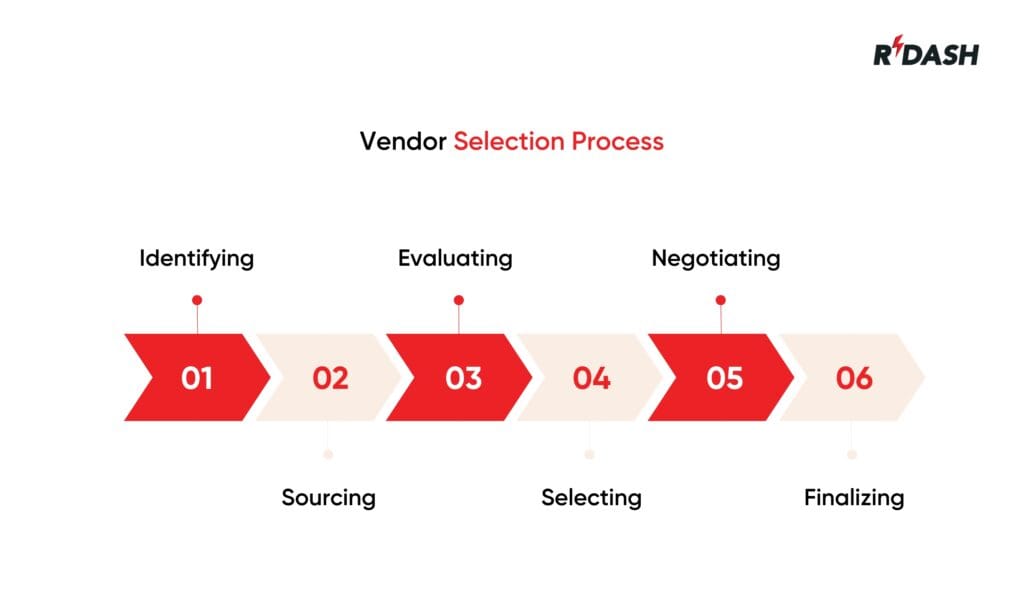

What is the vendor selection process

Vendor selection in the industry is a systematic process designed to guarantee that projects are supplied with high-quality materials and services at competitive prices. Here’s how it typically unfolds:

- Identifying Requirements: The first step is to clearly outline what the project needs. This includes specifying the type of materials, the quantity needed, and the services required to complete the project successfully.

- Sourcing Vendors: Once the needs are identified, the next step is to find potential vendors. This might involve seeking recommendations, researching online, or tapping into existing networks.

- Evaluating Vendors: After compiling a list of potential vendors, the evaluation process begins. This includes assessing each vendor’s reputation, experience, pricing, and ability to meet deadlines. Often, this step involves soliciting and reviewing bids or proposals from various vendors.

- Selecting the Vendor: Vendor selection is made based on criteria that might include cost, quality, reliability, and past performance. It’s crucial to choose a vendor who not only offers a competitive price but also has a proven track record of delivering quality materials and services on time.

- Negotiating Terms: Once a vendor is selected, the next step is to negotiate terms that cover pricing, delivery schedules, payment terms, and other contractual details. This ensures both parties are clear about expectations and responsibilities.

- Finalizing the Agreement: The final step is to formalize the agreement with a contract that binds both the vendor and the client to the agreed-upon terms, ensuring a clear legal framework for the partnership.

Why is vendor selection crucial?

Doing the right vendor selection is critical for several reasons:

- Quality Assurance: The quality of materials and services directly affects the stability, safety, and aesthetics of a construction project. High-quality vendors ensure that the finished project meets all required standards and regulations.

- Cost Management: Effective vendor selection can significantly affect the overall cost of a project. Securing competitive pricing without compromising on quality can help keep a project within budget.

- Timely Completion: Reliable vendors deliver materials and services on time, which is essential to keep the project on schedule. Delays in delivery can lead to costly project overruns.

- Risk Reduction: Working with reputable and reliable vendors minimizes the risks associated with poor quality materials, delayed deliveries, and contractual disputes.

- Building Relationships: Establishing a good relationship with dependable vendors can lead to smoother project execution and potential benefits on future projects through quicker negotiations and trusted services.

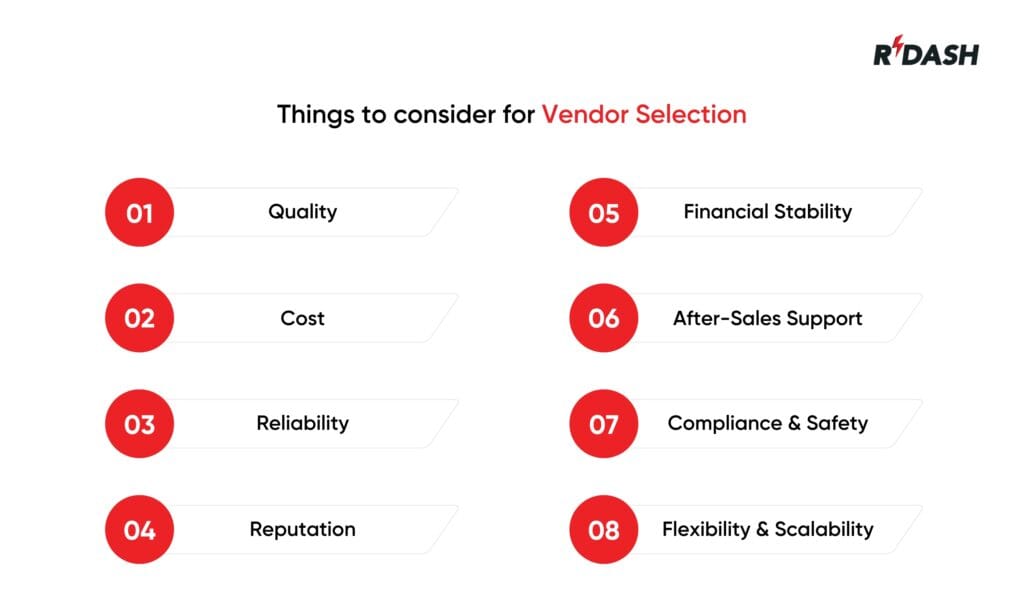

Things to consider for vendor selection

When doing vendor selection for a construction project, several critical factors should be considered to ensure you make the best choice for your needs and budget. Here are some key considerations:

- Quality of Products and Services: The quality of materials and workmanship provided by the vendor is paramount. Ensure that the vendors have a good track record of supplying high-quality products that comply with all relevant standards and regulations.

- Cost Effectiveness: While quality shouldn’t be compromised for cost, it’s important to ensure that the pricing offered by the vendor is competitive and aligns with your project budget. Look for vendors who provide the best value for money.

- Reliability: It’s essential that the vendor consistently delivers goods and services according to schedule. Delays can cause significant disruptions to the project timeline and increase costs. Check the vendor’s history for reliability and adherence to schedules.

- Experience and Reputation: Consider the vendor’s experience in the construction industry, especially with projects similar to yours. A reputable vendor is likely to offer more reliable and efficient service based on their industry knowledge.

- Financial Stability: It’s important to ensure that the vendor has the financial stability to deliver throughout the project duration. Financially unstable vendors might fail to deliver essential supplies, impacting project timelines.

- After-Sales Support: Good after-sales support, such as handling returns, resolving complaints, and providing technical support, is essential. This can significantly ease the management of materials and services throughout the project.

- Compliance and Safety: Make sure the vendor complies with all industry safety standards and regulations. This reduces the risk of legal issues and ensures that safety practices are followed on the project site.

- Flexibility and Scalability: Vendors should be able to adapt to changes in project requirements and scale their services up or down based on your needs. This flexibility can be crucial in responding to unexpected changes or challenges.

For a deeper dive into how to manage and optimize these vendor relationships throughout the lifecycle of your construction projects, check out our comprehensive guide on supplier relationship management here.

Steps in the vendor selection process

The vendor selection process in construction is methodical and structured to ensure the best fit for the project. Here’s how it typically goes:

- Define Your Criteria: Before you start looking for vendors, clearly define what you need in terms of materials, services, timelines, and other project-specific requirements. This will establish the foundation for your criteria during the selection process.

- Gather a List of Potential Vendors: Research potential vendors through online searches, industry recommendations, or by attending trade shows and conferences. This initial list should be comprehensive to ensure all possible options are considered.

- Send Out Requests for Information (RFIs): An RFI helps gather general information from potential vendors, such as company background, product ranges, and initial pricing. This helps in narrowing down the list to those who best fit your criteria.

- Evaluate Proposals and Conduct Assessments: Once RFIs are returned, evaluate the responses based on your criteria. You may also want to conduct site visits, check references, or review sample materials to assess the quality of the vendors’ offerings.

- Request for Proposals (RFPs): For vendors that make it through the initial screening, send out RFPs to get detailed proposals on pricing, delivery timelines, and specific terms and conditions. This step is crucial for making comparisons between vendors.

- Negotiate Terms: Once you’ve selected your top choices, negotiate terms that are favorable but fair. Discuss pricing, payment terms, delivery schedules, and other contractual details.

- Make the Final Selection: Choose the vendor that best meets all the defined criteria and with whom you’ve successfully negotiated terms. Ensure this choice is documented with a formal agreement or contract.

- Monitor and Evaluate: After selection, continuously monitor the vendor’s performance against the agreed terms. Regular evaluation and feedback can help maintain a good vendor relationship and ensure continuous improvement.

The vendor selection process is critical in construction, affecting everything from project timelines to quality and cost. Following these steps diligently can significantly improve the chances of project success.