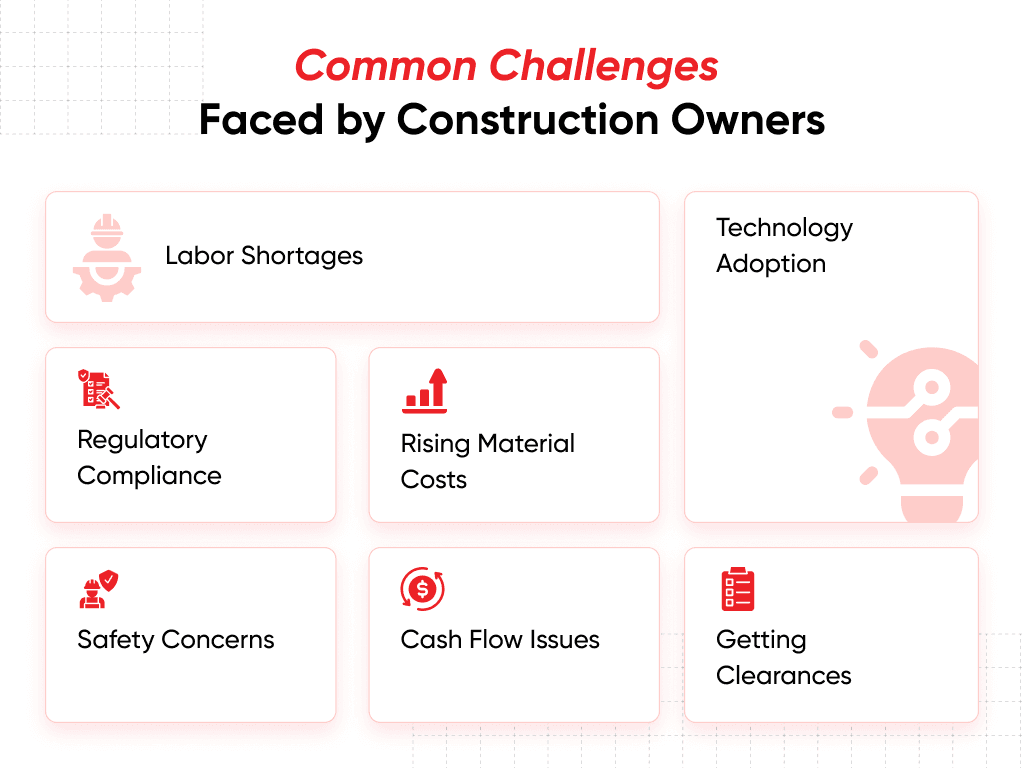

Common Challenges Faced by Construction Owners

Owning a construction business is not just about building structures – it’s about managing people, inventory, budget, regulations, and deadlines all at once. Each project is unique, but certain challenges are common across the industry. Understanding these issues in detail can help owners prepare better strategies to overcome them.

1. Labor Shortages

The shortage of skilled workers is one of the biggest challenges in the construction industry. Many seasoned workers are leaving the industry, while fewer young professionals are choosing construction as a career. This has created a gap in skilled trades such as masonry, carpentry, welding, and electrical work.

Without enough trained workers, projects take longer to complete, and labor costs increase as companies compete for limited talent. In some cases, owners may have to hire less experienced workers, which can affect the quality of work and increase the need for rework. To address this, construction owners need to focus on training programs, apprenticeship opportunities, and offering competitive wages and benefits to attract and retain skilled labor.

2. Technology Adoption

Unlike industries such as manufacturing and IT, which have quickly adopted digital tools, the construction sector has been slower to embrace technology. Many owners still depend on manual methods like paper forms, WhatsApp, and spreadsheets to manage projects. This leads to delays, errors, and miscommunication between teams.

The hesitation often comes from concerns about cost, lack of training, or resistance to change among employees. However, using construction management software, drones, and real-time reporting tools can save time, reduce mistakes, and improve collaboration. Owners who fail to adapt risk falling behind competitors who are leveraging technology to deliver faster and more cost-effective projects.

3. Regulatory Compliance

Construction work must meet a variety of regulations, from building codes and safety guidelines to environmental compliance requirements. These rules can vary depending on the location and type of project, and failing to follow them can lead to fines, penalties, or even project shutdowns.

Regulatory compliance also requires thorough documentation, regular inspections, and close coordination with local authorities. For example, safety regulations might require training certifications for workers, while environmental laws might require specific waste disposal methods. Keeping track of all these requirements is time-consuming but necessary. Using digital compliance checklists and hiring dedicated compliance managers can help streamline the process.

4. Rising Material Costs

The cost of construction materials like cement, steel, wood, and glass can rise suddenly due to market fluctuations, supply chain issues, or changes in import/export policies. For example, global shortages of steel or timber can cause prices to spike, making it difficult for owners to stick to their project budgets.

When material costs increase after a contract has been signed, owners often have to absorb the extra expense or renegotiate with clients. This can put pressure on profit margins and create challenges in maintaining strong client relationships.

To manage this risk, construction owners can negotiate long-term contracts with suppliers, purchase materials in bulk when prices are low, or use alternative materials that are more cost-stable.

5. Safety Concerns

Safety is a top priority in construction because job sites are full of potential hazards – working at heights, handling heavy equipment, and dealing with electrical systems, to name a few. Accidents can cause injuries, project delays, and legal liabilities, as well as damage to a company’s reputation.

Owners must ensure that all safety protocols are followed, from providing personal protective equipment (PPE) to conducting regular safety training sessions. Regular site inspections can help identify hazards early, and safety management software can be used to track incidents and ensure compliance with safety regulations. Promoting a strong safety culture not only safeguards workers but also boosts efficiency by minimizing delays caused by workplace incidents.

6. Cash Flow Issues

Even profitable projects can suffer from cash flow problems if payments from clients are delayed or if expenses pile up faster than revenue comes in. Construction projects often require large upfront investments for materials, labor, and equipment before any payment is received from the client.

Late payments can make it hard to pay workers and suppliers on time, which can lead to work stoppages or strained relationships with vendors. To avoid cash flow issues, owners should set clear payment schedules in contracts, track invoices closely, and keep a financial buffer to cover unexpected expenses. Using accounting software designed for construction can give owners real-time visibility into cash flow, helping them make informed financial decisions.

7. Getting Clearances

Before and during construction, projects often require approvals from various authorities – municipal bodies, environmental agencies, safety inspectors, and more. Each clearance can take time, involve extensive paperwork, and require multiple follow-ups.

Delays in getting these approvals can hold up the start or progress of a project, causing financial strain and extending timelines. The process can be even more challenging when projects are large and involve multiple government departments. Owners can speed up approvals by preparing all necessary documentation in advance, hiring consultants familiar with local processes, and maintaining good relationships with approval authorities.

How RDash can help

RDash helps construction owners tackle common challenges by streamlining project workflows, improving cash flow visibility, and enabling real-time collaboration across teams. With digital tools for scheduling, approvals, and progress tracking, it reduces delays, controls costs, and keeps projects compliant and on track.

FAQs

1. What is the biggest challenge for construction owners today?

Labor shortages remain a major concern, as they affect both timelines and quality.

2. How can construction owners manage rising material costs?

By locking in prices through long-term supplier contracts, bulk purchasing, and using cost tracking tools to monitor spending.

3. Why is adopting technology important in construction?

Technology improves accuracy, speeds up communication, reduces errors, and helps keep projects on schedule and budget.

4. What steps can be taken to minimize safety hazards on construction sites?

Through regular training, proper use of PPE, frequent safety inspections, and enforcing compliance with safety protocols.

5. What’s the best way to speed up clearance approvals?

Submit complete paperwork early, hire experts familiar with the process, and use project tracking tools to monitor approval stages.