What Is Construction Cost Analysis?

Construction cost analysis is the process of carefully studying and breaking down all the costs involved in a construction project. It helps project managers, contractors, and clients understand where money is being spent and how to manage it better.

This analysis looks at both direct and indirect costs. Direct costs include things like materials, labor, and equipment – anything directly involved in the building work. Indirect costs are expenses that support the project, such as site security, permits, and administration costs.

By doing a cost analysis, teams can compare estimated costs with actual spending. This helps spot any differences, understand why they happened, and take corrective actions early. It also helps in setting more accurate budgets for future projects.

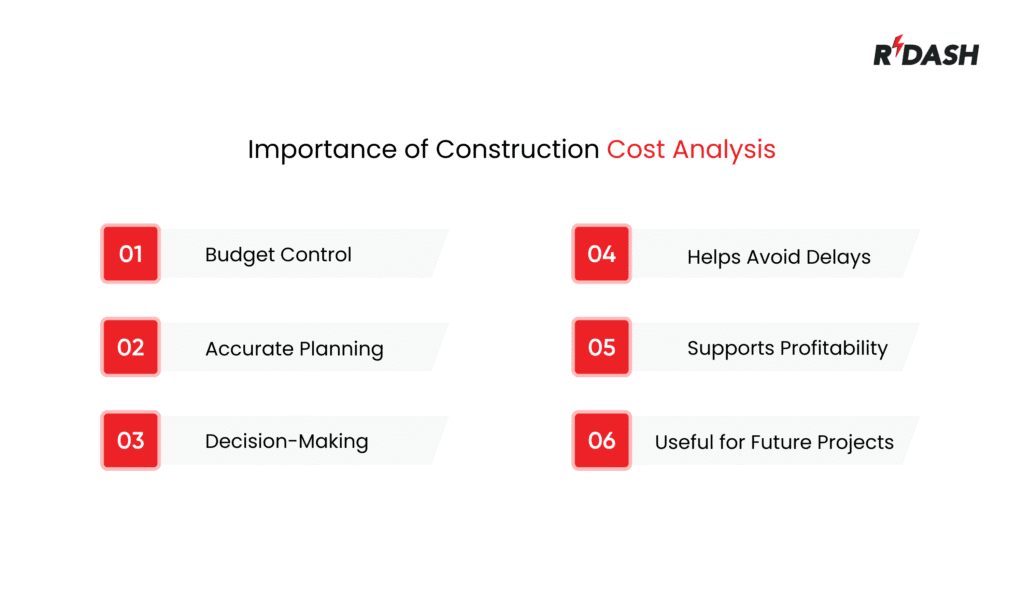

Importance of a Construction Cost Analysis

- Better Budget Control

Cost analysis helps track how money is being spent across each part of the project. This makes it easier to stick to the budget and avoid unexpected costs. - Accurate Planning

When teams know the cost of each task and material, they can create more realistic project plans. This leads to better timelines and smoother execution. - Improved Decision-Making

By analyzing costs regularly, project managers can make smart choices about where to cut expenses, what materials to use, or whether to hire extra labor. - Helps Avoid Delays

Unexpected costs often cause delays. A proper cost analysis highlights financial risks early, so teams can fix issues before they become bigger problems. - Supports Profitability

For contractors and construction companies, cost analysis helps maintain profit margins by reducing waste and managing resources efficiently. - Useful for Future Projects

The data gathered during cost analysis is valuable for future planning. It gives insights into what worked, what didn’t, and how to budget better next time.

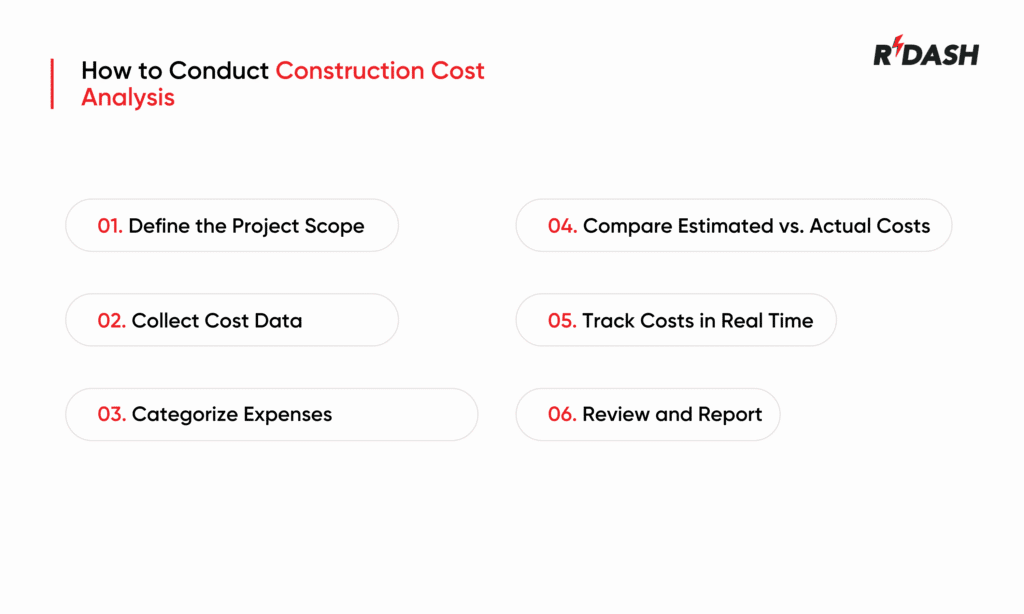

How to Conduct Construction Cost Analysis

Conducting a construction cost analysis involves a few clear steps that help break down and understand all project expenses. Here’s how it’s usually done:

- Define the Project Scope

Start by clearly outlining what the project includes. This helps identify what costs will be involved, such as materials, labor, equipment, and services. - Collect Cost Data

Gather cost information from different sources, like supplier quotes, labor rates, rental charges, and previous project records. Be sure to include both direct and indirect costs. - Categorize Expenses

Group costs into categories such as materials, labor, equipment, permits, utilities, and overheads. This makes it easier to track spending and compare with your budget. - Compare Estimated vs. Actual Costs

Check how the actual spending compares to the original estimates. Any differences should be noted and analyzed to understand the cause—whether it’s due to price changes, delays, or mistakes. - Track Costs in Real Time

Use tools or software to monitor spending during the project. Keeping real-time records helps catch issues early and make timely adjustments. - Review and Report

At the end of the project (or at key stages), review the cost data. Prepare a report that highlights what went well, where overspending occurred, and what can be improved in the future.

Benefits of Construction Cost Analysis

Construction cost analysis offers several advantages that help improve project performance and financial control:

- Better Cost Control

By regularly analyzing costs, teams can avoid overspending and keep the project within the planned budget. - Informed Decision-Making

Having clear cost data allows project managers to make smarter decisions about resource use, design changes, or contractor selection. - Improved Resource Management

Knowing where money is going helps allocate resources more efficiently, reducing waste and avoiding unnecessary purchases. - Helps Prevent Delays

Cost issues can cause project delays. Cost analysis helps detect problems early so they can be fixed before affecting the timeline. - Supports Transparency

Sharing cost reports with stakeholders builds trust by showing that funds are being managed responsibly. - Useful for Future Planning

Insights from past cost analysis can be used to estimate budgets and plan better for upcoming projects, making them more efficient and predictable.

How to Maximise the Use of Construction Cost Analysis

Doing a cost analysis is useful, but knowing how to fully use the information is what makes the biggest impact. Here are some ways to get the most value from your construction cost analysis:

- Review Cost Data Regularly

Don’t wait until the end of the project to analyze costs. Review the data weekly or at key milestones to stay updated on spending and spot problems early. - Use Digital Tools

Construction management software can help track costs in real time. Digital tools reduce errors, save time, and make it easier to organize and understand cost data. - Link Cost Analysis to Project Progress

Make sure your cost analysis is connected to actual site progress. For example, if 60% of work is complete, the spending should match that level. If not, investigate why. - Train Your Team

Ensure that everyone involved – engineers, site supervisors, and finance teams, understands the value of cost analysis. When teams are trained to log and track expenses properly, reports become more accurate and useful. - Use Insights to Make Improvements

After reviewing cost data, apply the lessons to improve your current and future projects. Whether it’s adjusting material choices or changing how you schedule labor, use the analysis to take meaningful action. - Share Reports With Stakeholders

Make your cost findings easy to understand and share them with clients, partners, or senior management. This builds trust and supports better decision-making across the project.

Construction Cost Analysis Reporting

A construction cost analysis report is a summary document that presents how money is being spent across a project. A good report helps teams and stakeholders understand financial performance clearly. Here’s what to include:

- Project Overview

Include basic project details – location, client name, start and end dates, and current stage of progress. - Estimated vs. Actual Costs

Show a comparison between planned costs and actual spending for each category (materials, labor, equipment, etc.). Use tables or graphs to make this easy to read. - Cost Variances

Highlight any areas where actual costs are higher or lower than expected. Explain the reasons for these differences, such as price hikes, delays, or scope changes. - Resource Usage

Track how materials and manpower were used. This helps show whether resources are being managed efficiently or if there’s waste. - Cash Flow Summary

Add a simple timeline showing when money was spent, helping to see if spending matched the planned schedule. - Recommendations and Action Points

End the report with key takeaways—what worked well, what needs to be fixed, and suggestions for improving future projects.

FAQs

1. What is construction cost analysis?

It’s the process of examining all costs involved in a construction project to understand spending patterns, compare estimates with actuals, and improve financial control.

2. Why is cost analysis important in construction?

It helps prevent overspending, supports better budgeting, and allows for early identification of financial risks or inefficiencies.

3. What are the key components of a cost analysis report?

A typical report includes estimated vs. actual costs, cost variances, resource usage, cash flow timelines, and key takeaways or recommendations.

4. How often should cost analysis be done during a project?

Ideally, it should be reviewed regularly, weekly or monthly – depending on the size and speed of the project.

5. What tools are used for construction cost analysis?

Construction management software like RDash can help track, organize, and report cost data in real time.

6. Who is responsible for conducting construction cost analysis?

Usually, the project manager or cost control team oversees the analysis, but accurate data often comes from site engineers, procurement teams, and accounts.

7. Can cost analysis help reduce project delays?

Yes. Identifying cost issues early can prevent financial bottlenecks that lead to delays in materials, labor, or approvals.

8. How does construction cost analysis support future projects?

By learning from past spending data, teams can create more accurate budgets, improve procurement strategies, and avoid repeating the same mistakes.