In construction, a snag list or snags refers to a compilation of tasks that must be addressed or corrected before a project can be deemed complete. This list is typically compiled towards the end of a construction project during the final inspection phase. It details the minor issues, defects, or unfinished work that must be addressed for the project to meet the agreed-upon standards and specifications. These might include cosmetic blemishes, such as paint touch-ups or fixing a sticking door, or more substantive issues like adjustments to electrical fixtures or plumbing.

The purpose of a snags is not just to correct faults but to ensure that every aspect of the project is finished to the highest quality, adhering to both the vision of the client and compliance with building regulations. Creating a comprehensive snag list is a crucial step in the quality assurance process, ensuring that all elements of the project are complete and satisfactory before the final handover.

What is a Snag List?

A snag list, also know as a punch list, is a document prepared toward the end of a construction project to identify any remaining tasks or issues that need to be addressed. It highlights tasks that are incomplete, need fixing, or require adjustments before the project can be officially handed over. These are usually small issues such as repairs, finishing touches, testing equipment, or replacing damaged items. Its main goal is to ensure the completed project meets the agreed specifications and maintains the required quality standards. It also ensures that any damage or errors that occurred during construction are corrected before the project is closed out.

When are construction snag lists typically executed?

Snags are typically executed in the final stages of a construction project, just before the project is completed. However, to enhance efficiency, it’s beneficial to adopt a more dynamic approach:

- During Construction: Introducing snag points at various stages of construction can help in managing defects more systematically. For instance, after each major phase like framing, electrical, and plumbing, a mini-snag list can be compiled and addressed.

- Pre-Handover Inspection: The most critical snag list is often conducted as part of the pre-handover inspection. This comprehensive review is designed to ensure that everything in the project meets the contract specifications and quality standards.

How do stakeholders interact with a construction snag list?

A snag list in construction is a critical document that captures details about issues that need resolution before a project can be declared complete. Its successful execution requires a collaborative effort among various stakeholders, each playing a unique role. Understanding how these stakeholders—owners, contractors, subcontractors, and architects/designers—interact with the snag list is essential for smooth project completion and client satisfaction.

Owner

The project owner’s interaction with the snag list is primarily focused on review and approval. Once the contractor presents the snag list, the owner examines it to ensure all aspects of the construction meet their expectations and the standards outlined in the initial agreement. The owner may walk through the construction site with the contractor to visually confirm the items listed and may also add any new issues they observe. Their approval is crucial because it signifies agreement that the work, once corrected, will fulfill the contract terms, allowing for the final handover of the project.

Contractor

The contractor plays a central role in the snag list process. Initially, it is up to the contractor, typically in collaboration with the project manager, to compile the snag list. This involves a thorough inspection of the construction site to identify and document any unfinished tasks or issues. After compiling the list, the contractor presents it to the owner for approval and discusses how and when the items will be addressed. Post-approval, the contractor coordinates with subcontractors to ensure all snags are rectified and often conducts a final review to ensure all corrections meet the required quality standards before inviting the owner for a final walk-through.

Subcontractors

Subcontractors receive specific portions of the snag list relevant to their scope of work from the contractor. Their role is to address the detailed issues within their expertise, whether it involves electrical fittings, plumbing, carpentry, or finishing works. Efficient correction of these items is vital as it directly impacts the overall project timeline and quality. Once they have completed their tasks, they notify the contractor, who will then check the work against the snag list standards.

Architect/Designer

Architects or designers, while not involved in the physical correction of snags, play an advisory and oversight role in the snag list process. They may be called upon to clarify the design or architectural intent of specific elements noted in the snag list, ensuring that the corrections align with the original plans and specifications. Architects also participate in some of the site walkthroughs, particularly for snags that involve aesthetic or functional aspects of their design, to confirm that the execution aligns with their design vision.

Common snags found in construction projects

Paint Touch-ups and Surface Finishing

Small issues such as uneven paint, scuff marks, or surfaces that haven’t been properly finished. These are often the result of rushed work or oversight during the finishing phase.

Electrical Issues

Problems such as faulty wiring, outlets not functioning correctly, or lighting that’s not installed to specifications. Electrical issues can be both a safety hazard and a delay.

Plumbing Leaks or Faulty Fixtures

Leaks, low water pressure, or improperly installed plumbing fixtures. These issues often arise after the system is in use and can cause significant damage if not addressed quickly.

Incorrect Dimensions or Misalignment

This might include doors and windows that don’t align correctly, walls that are out of place, or floors that are uneven.

Damaged Materials or Finishes

Construction materials like tiles, flooring, and windows may become damaged during handling or installation. These need to be replaced or repaired before final approval.

Incomplete Work

Areas where work was left unfinished or parts of the project were not completed as specified. This could involve missing trim, incomplete framing, or flooring that is left unfinished.

Structural Defects

More significant issues, like cracks in the walls or foundation-related concerns, that need immediate attention to ensure the building’s stability.

Safety Hazards

Any hazards that pose a risk to safety on site, such as improperly installed handrails, loose scaffolding, or exposed wires. These need to be fixed before the site can be cleared for occupancy.

Cleaning and Site Conditions

Construction sites often need thorough cleaning once the work is done. Issues such as leftover debris, dust, and unfinished landscaping are common snags that need to be addressed before the final handover.

Regulatory Compliance Issues

Missing or incomplete documentation for safety inspections, building code violations, or failure to meet local regulations. These snags need to be resolved before the project can receive final approval from local authorities.

HVAC and Ventilation Issues

Problems with heating, ventilation, and air conditioning systems, such as poor airflow or unbalanced systems. These problems can make the space uncomfortable or unsafe to occupy.

Defective Doors and Windows

This includes doors that don’t open or close properly, windows that leak, or seals that are not correctly installed. These issues can affect both the functionality and energy efficiency of the building.

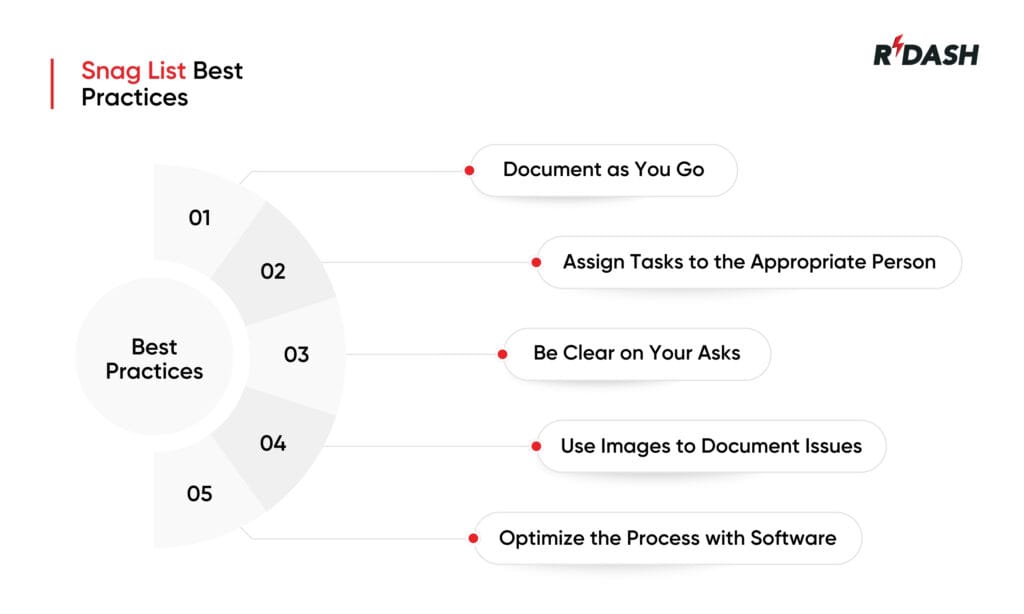

Snag List Best Practices

In the construction industry, maintaining high standards of quality is non-negotiable. One essential tool that helps achieve this is the snag list—a dynamic document that tracks unresolved issues requiring attention before a project can be completed. Implementing best practices for managing a snag list not only ensures that all issues are addressed promptly but also enhances the overall efficiency and quality of the construction process. Here are some proven strategies to optimize your snag list management:

1. Document as You Go

The most effective snag lists are those that are updated in real-time. It’s crucial to document issues as soon as they arise. Delaying documentation can lead to forgotten details and unaddressed problems, which can spiral into bigger issues later. By recording snags immediately, you ensure that nothing gets overlooked and that all issues are captured accurately.

2. Assign Tasks to the Appropriate Person

Once an issue is documented, it should be assigned immediately to the appropriate team member or subcontractor who is best equipped to resolve it. Clear assignment prevents confusion about responsibilities and ensures that issues are addressed by the right expertise. This practice not only speeds up the resolution process but also helps in tracking accountability throughout the project lifecycle.

3. Be Clear on Your Asks

Clarity is key when it comes to resolving snags efficiently. Each entry on the snag list should clearly describe the issue, suggest possible solutions if applicable, and set a reasonable deadline for resolution. Providing detailed, actionable descriptions helps prevent back-and-forth communication and ensures that everyone involved understands what is required to resolve the issue.

4. Use Images to Document Issues

Including images in your snag list can significantly enhance the clarity of the issues reported. Photos provide visual proof of the problem, help in assessing the extent of the issue, and serve as a valuable reference for before and after comparisons once repairs have been made. This practice is particularly useful for ensuring that all parties have a clear understanding of what needs to be fixed.

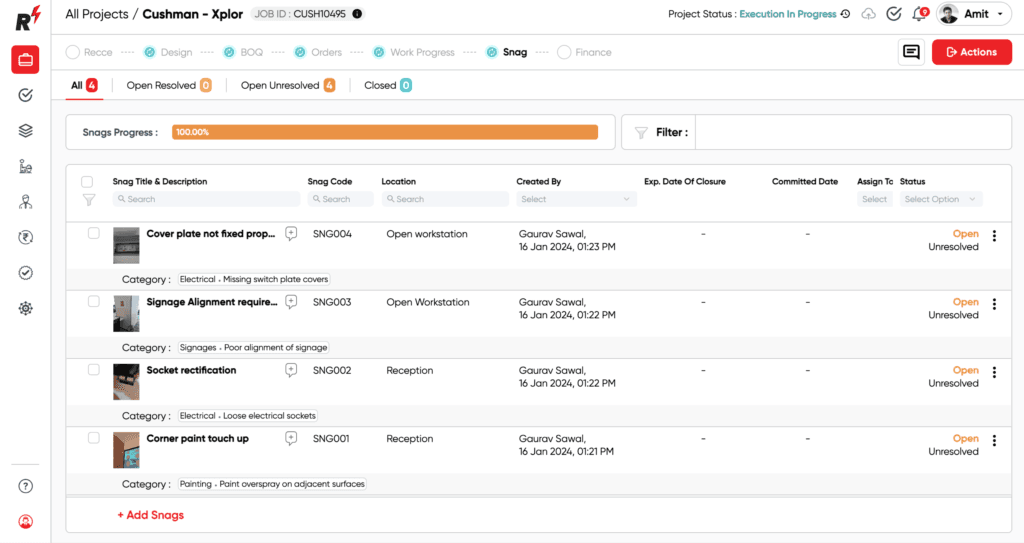

5. Optimize the Process with Software

Leveraging technology can transform the efficiency of your snag list management. There are numerous software solutions designed specifically for construction management that include features for creating, updating, and tracking snag lists. These tools often offer capabilities such as mobile access, integration with other project management functions, real-time updates, and collaborative tools that allow multiple users to view and edit the snag list simultaneously. By using software to manage your snag lists, you can streamline communication, improve response times, and maintain a centralized record of all issues and resolutions.

RDash simplifies snag list management by providing a clear platform to list items, assign tasks, and monitor progress. As RDash is optimized for mobile devices, you can manage your snag list directly from the jobsite – assigning tasks, capturing images, and documenting issues on the go. Discover how you can quickly create a comprehensive snag list with RDash to achieve a zero-snag status before your next construction final walk-through.