🚀 New Feature Alert : Introducing RDash Activity Schedule! Plan, Track and Collaborate. Check Now

Project Case Study

Established in 1969 as a design and engineering firm, Semac has grown into one of India’s leading EPC companies. Headquartered in Gurugram with a team of over 100 professionals, Semac provides complete one-stop solutions, delivering industrial projects seamlessly from concept to final delivery. One of the biggest projects Semac has delivered is a 6.5 lakh square feet warehouse in Palwal, Haryana – demonstrating their expertise in executing large-scale turnkey developments.

Semac serves clients in automotive, FMCG, technology, and renewable energy sectors. Its proven ability to deliver projects on time and within budget has earned the trust of industry leaders including Adani, Volkswagen, Maruti Suzuki, Hindustan Unilever, ITC, PepsiCo, Coca-Cola, Wipro, TCS, Amazon, V-Mart, Hero Electric, and Borosil.

Poly Medicure Limited Facility

Palwal, Haryana

Industrial / Pharmaceutical Factory

Located in the industrial hub of Palwal, Haryana, this 86,500 Sqft facility for Poly Medicure represents a massive logistical and financial undertaking. With a Total Scope Value of approximately ₹70 Cr and a complex blend of civil, structural, and finishing works, the project team faced the classic construction challenge: “walking on a rope” to balance thin margins against a massive influx of vendor bills and site expenses. This project required orchestrating 60+ internal collaborators to ensure the facility was delivered on time and within the strict budget.

This was not just a construction job; it was a high-volume financial operation. The project faced three distinct challenges that manual methods could not sustain:

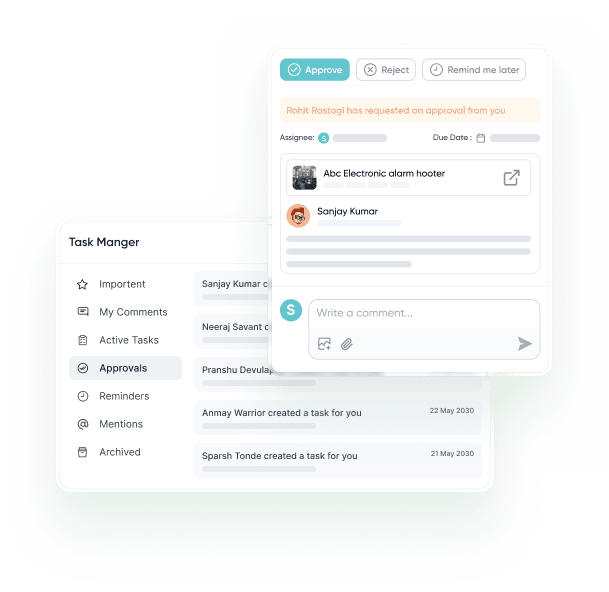

We deployed Rdash to bring the “Checkers” (Finance/Leadership) closer to the “Makers” (Site Team), ensuring that the massive volume of transactions was audited in real-time

Sorting the Invoices (The 3-Way Match)

The most critical win was digitising the procure-to-pay cycle.

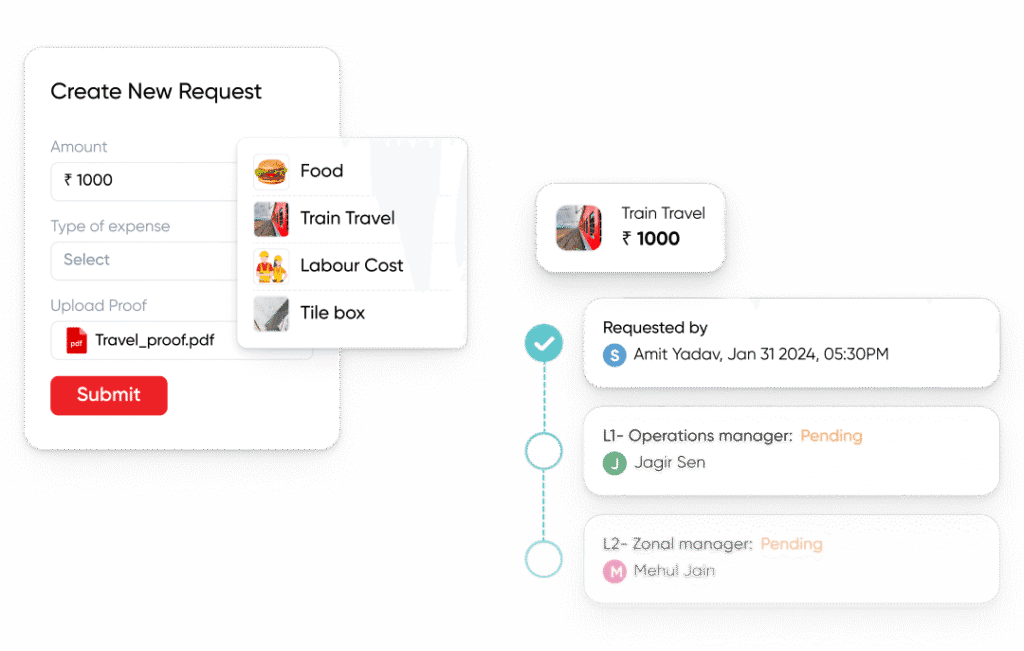

Granular Control on Site Expenses

With a site expense budget of ~₹7Cr, “gut feeling” approvals were not an option.

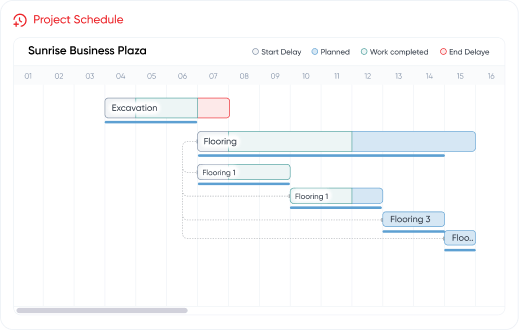

“4 Levels of Progress” Implementation

We moved beyond simple Gantt charts to a holistic view of the project:

Simply, fill out the form and our team will get back to you within 24 hours.

Fill out the form below and we will contact you as soon as possible.

Our Investors:

Our Investors:

Fill out the form below and we will contact you as soon as possible.

Manage leads, send quotations, convert to project

Schedule activities, set deadlines and highlight dependencies

Version control and contextual collaboration on design files

Create and Share BOQ with clients, Document and approve Changes

Automate 360° daily progress reporting - in real time

Smart site diligence and technical survey with mobile app

Tag quality snags to supplier orders

Linked to Element Master, automates procurement workflows

Automate PO creation, Configure country specific tax rules

Material GRN and Issuance at site store

Break scope items into standard materials

Precise cashflow control by measuring installed value of work

Capture and control site expanse via mobile app

Initiate Material Purchase Requests from site with Approval controls

Get advance analytics and get things done with Prompts

Turns contexts into collaborative Work Space

Makes your PO, Invoicing, Payment, and Expanse processes robust

Spec control with interactive element master

Create supplier/client logins to update documentation and provide approvals

50+ ready to plug dashboards, customised reports and MIS

Integrate with ERP, Accounting, and Business Applications

Our Perspective on Construction & Tech

Learn new concepts in Construction

These are our customer's success stories.

Insights on Construction & Interiors

In-depth research and analysis

Comprehensive Features Comparison

Complete Guide to Rdash

Our Perspective on Tech & Product