🚀 New Feature Alert : Introducing RDash Activity Schedule! Plan, Track and Collaborate. Check Now

Project Case Study

HPV Elevate is a pan-India HVAC and MEP services provider specialising in engineered cooling and building services for complex commercial and facility environments. Founded in 2007, the company has executed over ₹200 Cr worth of projects and operates with a team of 250+ professionals across multiple states.

HPV Elevate delivers turnkey HVAC solutions spanning concept and load studies, BOQ-led execution, retrofits, and uptime operations, integrating design, installation, and AI-enabled optimisation to reduce energy use and ensure reliable performance. Its services extend to electrical, fire protection, and civil interiors, making it a trusted partner for developers, data centres, and technical facilities where precision, uptime, and efficiency are paramount.

HDFC Bank, Candor Tech Space

Candor Tech Space, Kolkata

MEP

Executing a large-scale HVAC fit-out for a premier banking institution requires precision. Located in the bustling Candor Tech Space in Kolkata, this project involved a massive financial scope with a BOQ value of ₹7.76 Cr. The project focused on high-end HVAC implementation, requiring tight coordination between site engineering, inventory management, and a fragmented vendor network to ensure the facility was handed over operational and on budget.

This project presented three specific layers of difficulty that traditional Excel-based management could not handle:

RDash was deployed to move the project from “reactive” tracking to “proactive” financial governance. By digitising the workflow, we enforced the “Maker-Checker” rule, ensuring that every rupee spent had a digital footprint and an approval trail.

Plugged Margin Leakage in Procurement

Majority of margin leakage in construction projects traces back to not having a digital record of order elements issued to vendors. For HDFC, we moved the entire ordering process off Excel and email.

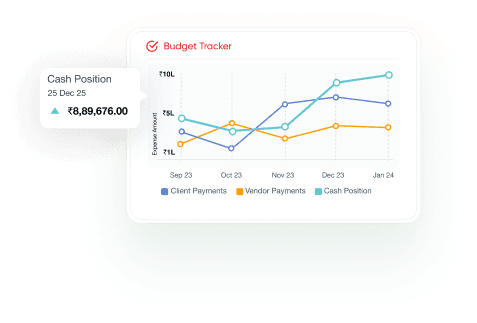

Enforced Cashflow Discipline (The 3-Way Match)

We established a strict digital thread from PO creation to Invoice Acceptance.

Site Reality vs. Reported Progress

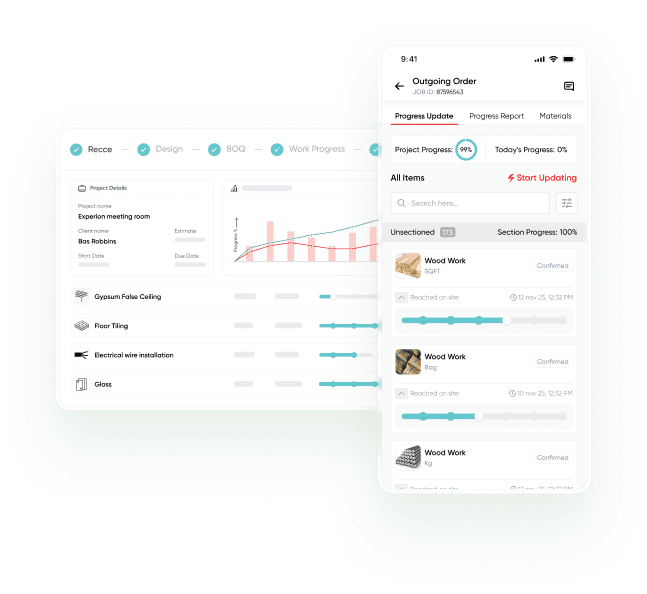

We moved beyond ad-hoc WhatsApp updates to structured Daily Progress Reports (DPRs).

Simply, fill out the form and our team will get back to you within 24 hours.

Fill out the form below and we will contact you as soon as possible.

Our Investors:

Our Investors:

Fill out the form below and we will contact you as soon as possible.

Manage leads, send quotations, convert to project

Schedule activities, set deadlines and highlight dependencies

Version control and contextual collaboration on design files

Create and Share BOQ with clients, Document and approve Changes

Automate 360° daily progress reporting - in real time

Smart site diligence and technical survey with mobile app

Tag quality snags to supplier orders

Linked to Element Master, automates procurement workflows

Automate PO creation, Configure country specific tax rules

Material GRN and Issuance at site store

Break scope items into standard materials

Precise cashflow control by measuring installed value of work

Capture and control site expanse via mobile app

Initiate Material Purchase Requests from site with Approval controls

Get advance analytics and get things done with Prompts

Turns contexts into collaborative Work Space

Makes your PO, Invoicing, Payment, and Expanse processes robust

Spec control with interactive element master

Create supplier/client logins to update documentation and provide approvals

50+ ready to plug dashboards, customised reports and MIS

Integrate with ERP, Accounting, and Business Applications

Our Perspective on Construction & Tech

Learn new concepts in Construction

These are our customer's success stories.

Deep dive into projects managed on RDash

Insights on Construction & Interiors

In-depth research and analysis

Comprehensive Features Comparison

Complete Guide to Rdash

Our Perspective on Tech & Product