🚀 New Feature Alert : Introducing RDash Activity Schedule! Plan, Track and Collaborate. Check Now

Project Case Study

GD Waldner is a specialist in designing, engineering, and delivering turnkey laboratory solutions that enable scientific, industrial, and educational innovation. They combine German design and technology with decades of local expertise to plan, construct, and equip advanced labs tailored to clients’ needs, focusing on safety, energy efficiency, and ergonomic functionality. Their offerings include laboratory furniture, fume hoods, process systems, and customised learning spaces, as well as installation, maintenance, and lifecycle support services across industries like pharmaceuticals, biotech, chemicals, healthcare, and education. GD Waldner positions itself as a long-term partner to help organisations create future-ready research environments.

Agratas Energy Storage Facility

Prestige Tech Cloud (Cirrus),

Bangalore

Industrial MEP / Energy Infrastructure

GD Waldner delivered a highly complex, high-value MEP infrastructure project for Agratas Energy Storage Solutions, supporting a specialised R&D facility spread across G+3 floors. The mandate involved the end-to-end execution of mechanical, electrical, and plumbing systems, designed to meet stringent technical, safety, and performance requirements typical of advanced energy infrastructure projects.

With a project value of ₹70 Cr, the scope covered over 3,600 MEP line items across HVAC, electrical systems, firefighting and specialised plumbing. Execution required tight coordination between 30+ vendors and a cross-functional internal team of 30 members spanning design, procurement, finance, project management and site supervision. The scale, data intensity and stakeholder complexity made this a mission-critical project where structured project controls and real-time visibility were essential.

MEP projects are notoriously data-heavy due to the high volume of components and dependencies.

GD Waldner utilized Rdash to digitize the commercial backbone of this heavy engineering project, moving from fragmented data to a unified “Maker-Checker” system.

Granular Inventory Intelligence (Ordered vs. Received)

With thousands of MEP components arriving on site, tracking exactly what was delivered against what was ordered is usually a manual nightmare.

The Logic: RDash linked site stock entries directly to ordered line items, creating an automatic Ordered vs. Received view for every SKU.

The Impact: The team tracked delivery status directly in RDash Insights with no manual spreadsheets, clearly seeing what was ordered versus received. This prevented over-acceptance and partial delivery of materials, maintaining visibility across ₹9.95 Cr of inventory.

Digitising the Procurement Chain

Unified Technical Coordination

Simply, fill out the form and our team will get back to you within 24 hours.

Fill out the form below and we will contact you as soon as possible.

Our Investors:

Our Investors:

Fill out the form below and we will contact you as soon as possible.

Manage leads, send quotations, convert to project

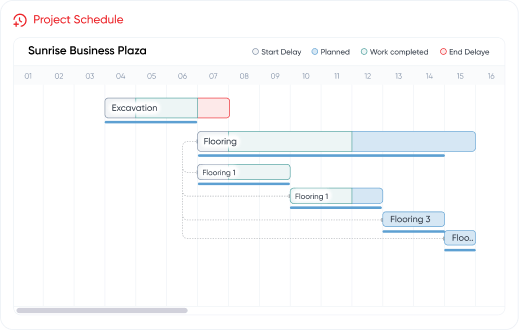

Schedule activities, set deadlines and highlight dependencies

Version control and contextual collaboration on design files

Create and Share BOQ with clients, Document and approve Changes

Automate 360° daily progress reporting - in real time

Smart site diligence and technical survey with mobile app

Tag quality snags to supplier orders

Linked to Element Master, automates procurement workflows

Automate PO creation, Configure country specific tax rules

Material GRN and Issuance at site store

Break scope items into standard materials

Precise cashflow control by measuring installed value of work

Capture and control site expanse via mobile app

Initiate Material Purchase Requests from site with Approval controls

Get advance analytics and get things done with Prompts

Turns contexts into collaborative Work Space

Makes your PO, Invoicing, Payment, and Expanse processes robust

Spec control with interactive element master

Create supplier/client logins to update documentation and provide approvals

50+ ready to plug dashboards, customised reports and MIS

Integrate with ERP, Accounting, and Business Applications

Our Perspective on Construction & Tech

Learn new concepts in Construction

These are our customer's success stories.

Insights on Construction & Interiors

In-depth research and analysis

Comprehensive Features Comparison

Complete Guide to Rdash

Our Perspective on Tech & Product